Process Stability and Control

Maintaining consistent process parameters across hundreds of tightly linked steps is critical, especially for advanced lithography and etching, to prevent variation and yield loss.

Driving precision and yield in semiconductor frontend manufacturing with camLine MES software, enabling end-to-end visibility and advanced process control.

In wafer fabrication, even the smallest process deviation can threaten yield and regulatory compliance. Managing complex process steps, thousands of recipes, and large data volumes requires structured execution to minimize setup errors and production variability. camLine's tailored MES solutions advance process control, provide real-time insights, and ensure full traceability, enabling first-time-right results, agile adaptation, and sustained leadership in the industry.

.png?width=149&height=100&name=Logos_ams-20250829-092441%20(1).png)

Challenges

Maintaining consistent process parameters across hundreds of tightly linked steps is critical, especially for advanced lithography and etching, to prevent variation and yield loss.

As chip designs advance to smaller nodes, even minor variations or contamination can lead to defects and costly rework. Rapid detection and immediate response are essential to uphold quality standards.

Managing thousands of recipes and parameters across multiple tools and shifts increases the risk of setup errors, data silos, and production variability.

Massive volumes of process and equipment data must be unified and accessible, supporting quick root cause analysis, compliance, and continuous improvement.

Meeting significant market growth and evolving technology requirements calls for flexible systems and accelerated adaptation, while maintaining quality and yield.

How we help

Who we help

We enable global fab networks to achieve seamless technology transfer and maintain consistent process quality across all sites with unified, end-to-end frontend semiconductor MES software.

We provide real-time monitoring and process control to meet strict quality and delivery goals. Our MES software offers flexible recipe management for accurate, agile production.

We support a wide variety of product types and frequent changes by delivering full traceability and visibility, with flexible control and recipe management for analog, micro-electro-mechanical systems (MEMS), and power device production.

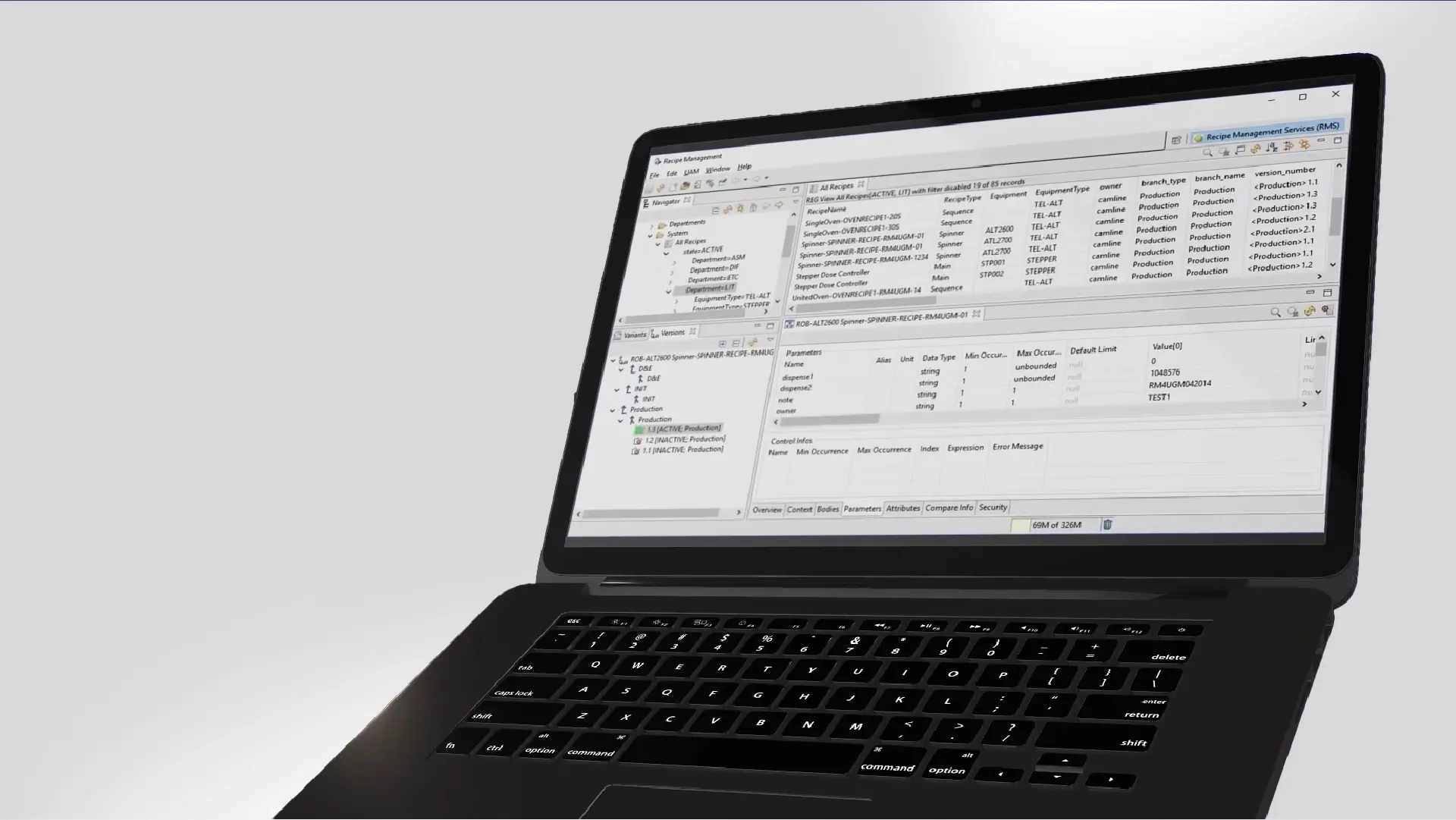

Recipes define all parameter settings and sequences for semiconductor production equipment, but managing them centrally and uniformly is challenging. In this Work Smarter video, learn how camLine’s recipe management solutions improve process integrity by standardizing recipe workflows and enhancing visibility through digital twin technology.

Recipes define all parameter settings and sequences for semiconductor production equipment, but managing them centrally and uniformly is challenging. In this Work Smarter video, learn how camLine’s recipe management solutions improve process integrity by standardizing recipe workflows and enhancing visibility through digital twin technology.

Our customer-focused consulting maximizes efficiency and quality in semiconductor manufacturing. With proven expertise, we deliver the best solutions for successful project implementation. Our software offers out-of-the-box capabilities and exceptional stability to support your success.

We believe successful software implementation requires more than great technology—it needs people who understand your business. Our co-development model with industry leaders ensures solutions address real-world challenges.

As your partner, we provide quality-driven MES/MOM solutions that transform data into a competitive advantage for high-tech industries.

Trusted by over 350 customers worldwide across various high-tech industries.

Empower manufacturers to achieve growth and excellence in over 40 countries globally.

Delivering proven manufacturing software solutions, from single-site pilots to global multi-site rollouts.

Modular MES systems with flexible modules that can be deployed step by step and expanded as operations grow.

Tailored MES/MOM solutions for different industries including solar, battery, semiconductor, and medical device.

Serving as the foundation of camLine MES, LineWorks SPACE supports quality assurance and advanced process control.

Our team is ready to deliver tailored solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.