Real-Time Monitoring and Control

Production Operations

- Manufacturing Execution System (MES)

- Recipe Management

- Equipment Integration

- Monitoring and Reporting

Quality Operations

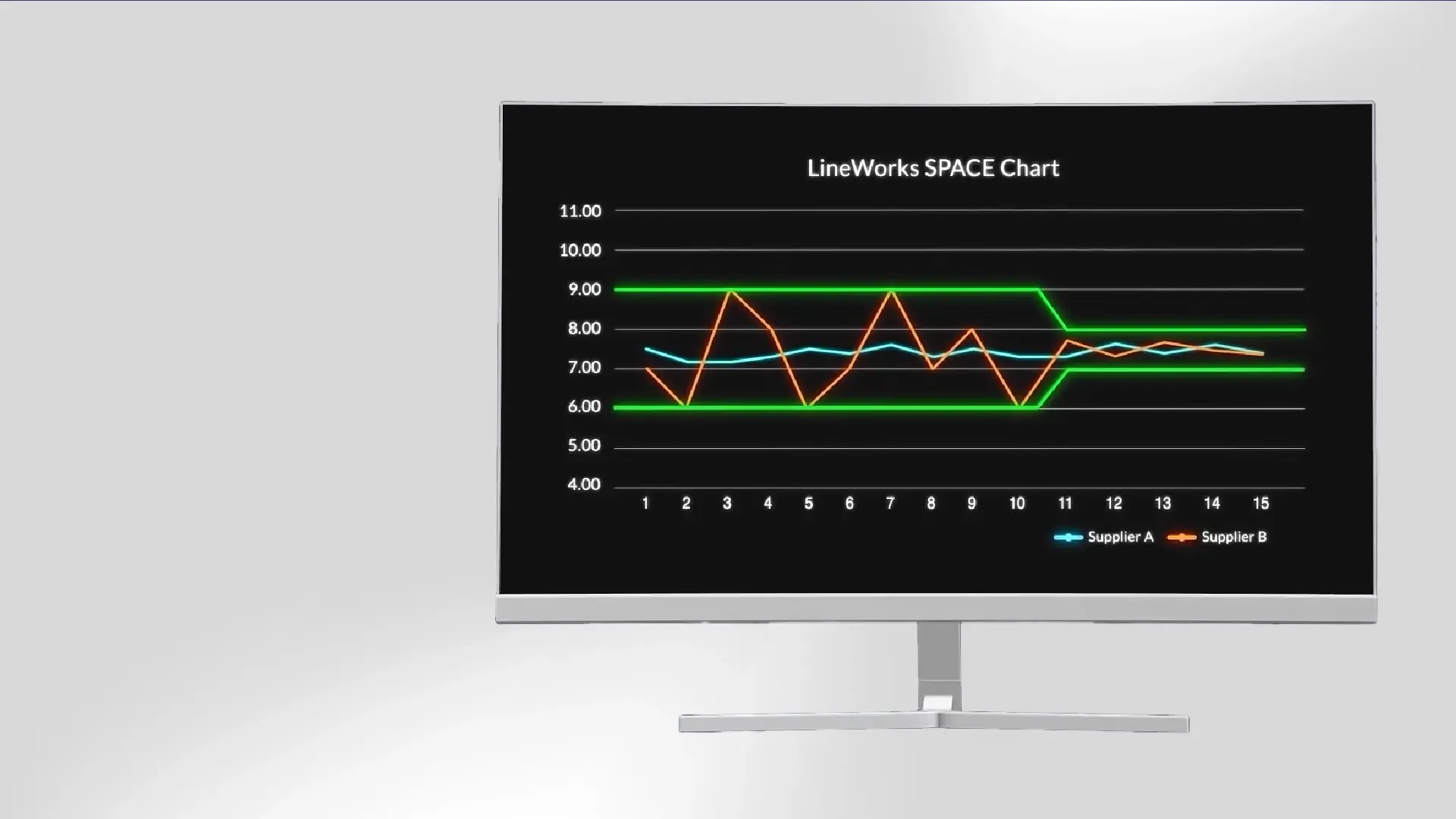

- Advanced SPC (Statistical Process Control)

- Advanced Process Control (R2R system)

- Security and Communication

Maintenance Operations

Inventory Operations

.png?width=149&height=100&name=Logos_ams-20250829-092441%20(1).png)

.png?width=303&height=100&name=Logos_azur%20space-20250829-092549%20(1).png)