Real Time Inventory Visibility in SMT Lines

In SMT manufacturing, ensuring a steady flow of materials to production lines is critical to avoiding disruptions and inefficiencies. With hundreds of different materials—each with specific validities and usage requirements—a lack of real-time inventory visibility can lead to production bottlenecks, excessive waste, and increased operational costs.

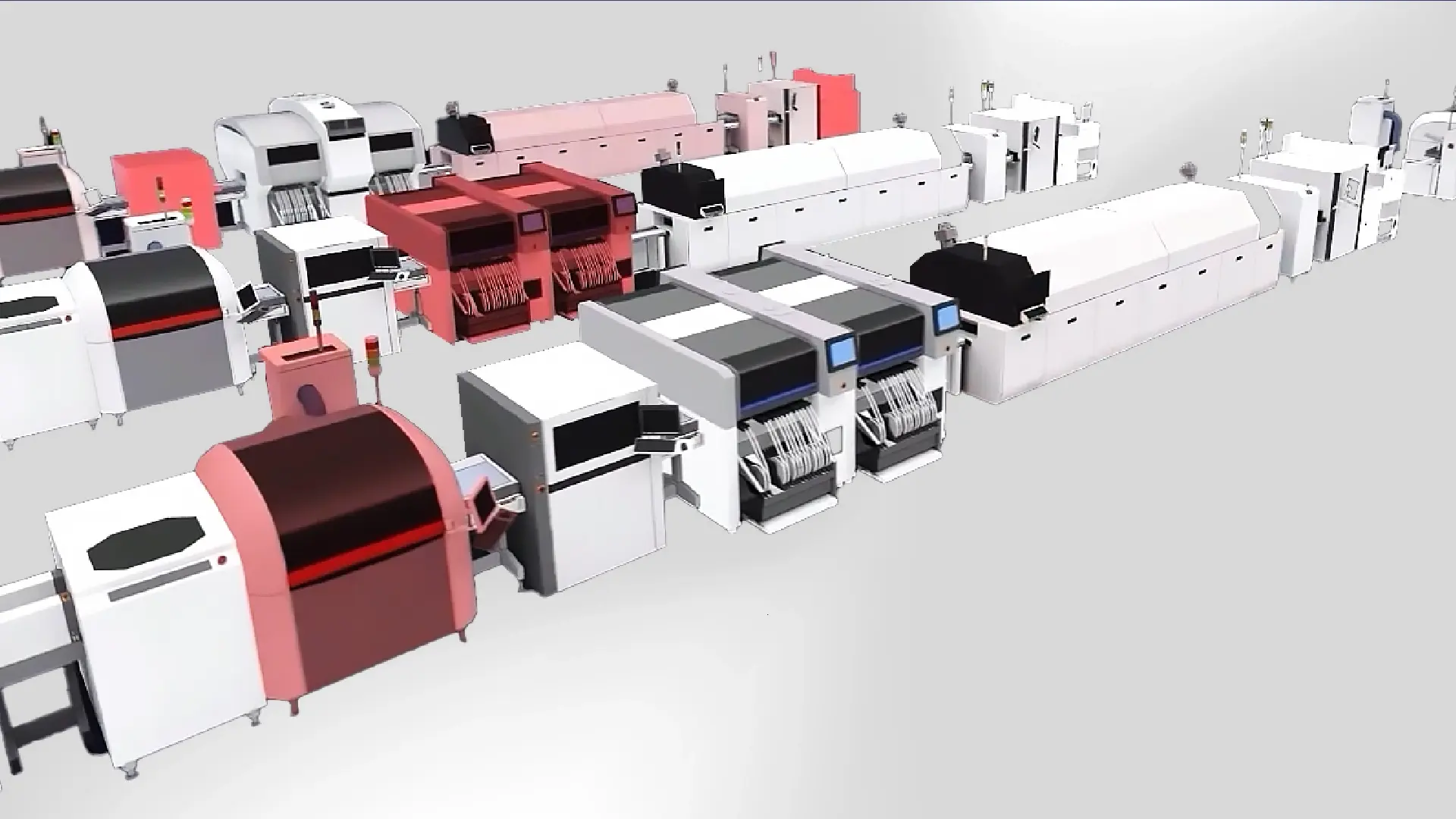

In this Work Smarter video, discover how camLine’s manufacturing software enhances SMT line inventory visibility—enabling Just-in-Time (JIT) material availability and optimizing operations for Industry 4.0.

Real Time Inventory Visibility in SMT Lines

In SMT manufacturing, ensuring a steady flow of materials to production lines is critical to avoiding disruptions and inefficiencies. With hundreds of different materials—each with specific validities and usage requirements—a lack of real-time inventory visibility can lead to production bottlenecks, excessive waste, and increased operational costs.

In this Work Smarter video, discover how camLine’s manufacturing software enhances SMT line inventory visibility—enabling Just-in-Time (JIT) material availability and optimizing operations for Industry 4.0.

Why is Transparent & Real-Time Inventory Data Crucial in SMT Assembly?

Maintaining real-time, up-to-date inventory visibility in SMT lines is essential for seamless production, waste reduction, and cost savings. With accurate material tracking and automated monitoring, manufacturers can:

- Prevent Production Delays: Ensure materials are available exactly when needed, minimizing machine stoppages.

- Reduce Excess & Waste: Optimize material usage by preventing overstocking or expiration of sensitive components.

- Enhance Decision-Making: Enable quick, data-driven responses to inventory shortages or unexpected demand fluctuations.

- Improve Product Quality: Maintain strict inventory control to meet industry standards and customer expectations.

Without real-time inventory data, manufacturers risk unplanned downtime, inefficient resource use, and delayed shipments—hindering overall production efficiency.

How LineWorks Suite Maximizes ROI in SMT Manufacturing

LineWorks Suite enhances SMT production efficiency by providing real-time insights into inventory visibility, material usage, and process optimization. With advanced monitoring and data-driven decision-making, LineWorks Suite enables:

- Real-Time Inventory Visibility: Helps manufacturers track material availability across SMT lines, ensuring Just-in-Time (JIT) production.

- Enhanced Traceability: Links material usage with production data to improve quality control and reduce inconsistencies.

- Optimized Process Efficiency: Provides insights into machine utilization and material flow, enabling smarter scheduling and reduced downtime.

- Data-Driven Quality Management: Supports better material allocation and defect prevention through integrated analytics.

By improving inventory transparency and process efficiency, LineWorks Suite empowers manufacturers to reduce operational waste, enhance resource utilization, and maintain a seamless production flow in SMT lines.

Subscribe to our newsletter

Get our latest updates and news directly into your inbox. No spam.