Achieve Precision and Control with Process Time Monitoring in SMT Lines

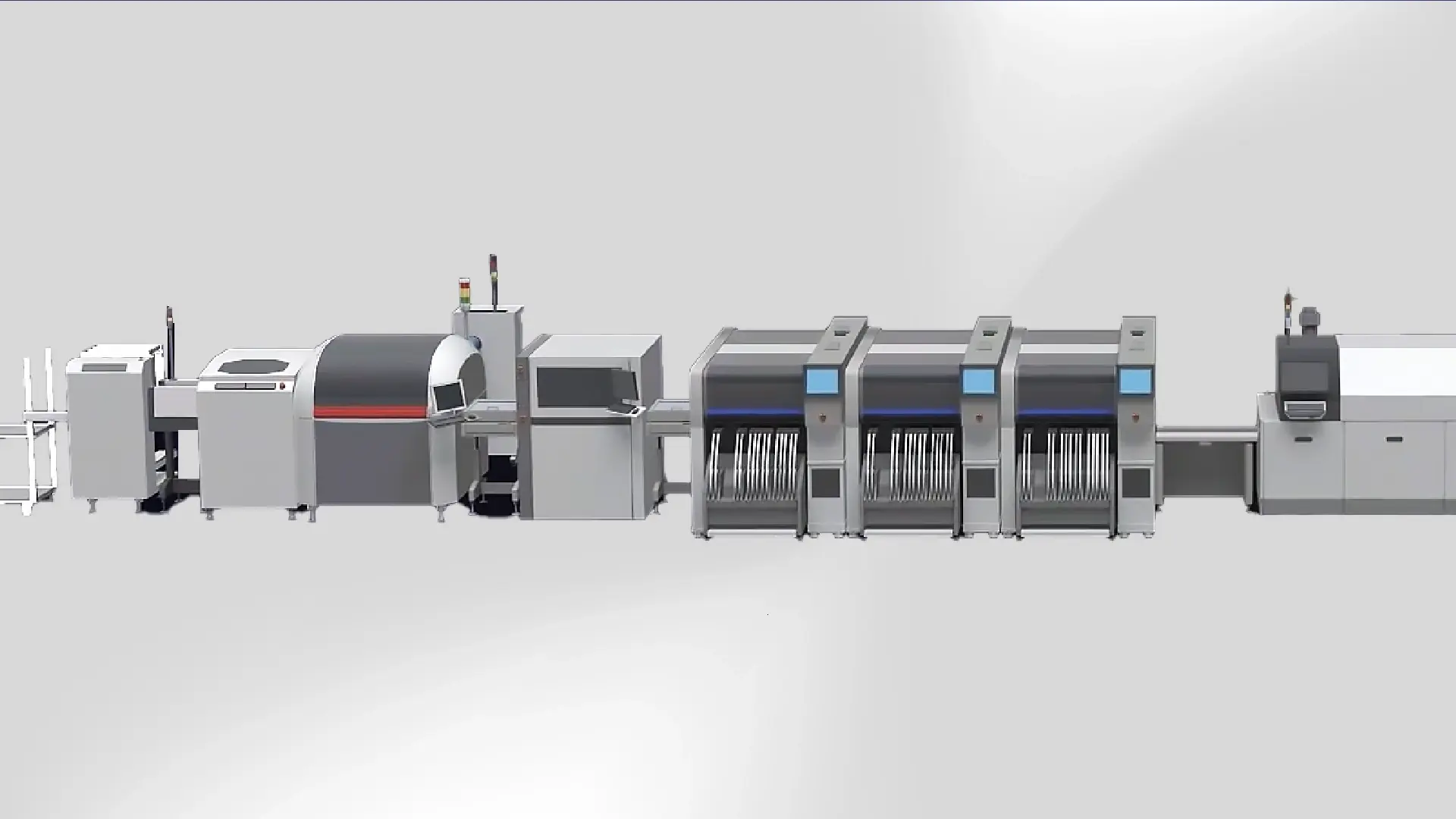

In Surface Mount Technology (SMT) manufacturing, ensuring precise process time control is essential for maintaining high product quality and seamless operations. Each step in the SMT assembly process—from solder paste application to component placement and reflow soldering—must adhere to strict timing conditions. Deviations in process timing can result in defects, increased material waste, and costly rework.

In this Work Smarter video, discover how camLine MES solution provides real-time process monitoring and automated timing validation, enabling self-monitoring equipment capabilities to maintain quality, efficiency, and production stability.

Process Time Control Over SMT Line with MES Solution

In Surface Mount Technology (SMT) manufacturing, ensuring precise process time control is essential for maintaining high product quality and seamless operations. Each step in the SMT assembly process—from solder paste application to component placement and reflow soldering—must adhere to strict timing conditions. Deviations in process timing can result in defects, increased material waste, and costly rework.

In this Work Smarter video, discover how camLine MES solution provides real-time process monitoring and automated timing validation, enabling self-monitoring equipment capabilities to maintain quality, efficiency, and production stability.

The Challenges: Maintaining Process Timing Across SMT Lines

Without real-time monitoring and automated process control, manufacturers face challenges that impact production quality and efficiency:

- Timing Deviations Impact Product Quality: SMT production involves time-sensitive processes, such as ensuring solder paste remains viable before components are placed. If a delay occurs, the paste can harden, leading to poor solder joints and defective PCBs.

- Downtime and Equipment Delays Affect Production Flow: A Pick and Place machine failure can disrupt the entire production timeline. Without a monitoring system, subsequent processes may continue, resulting in misalignment and wasted materials.

- Lack of Automated Timing Adjustments: Manual monitoring of process time increases human errors and delays in corrective actions. Without an automated system, manufacturers risk repeated process violations and unplanned reworks.

To overcome these challenges, manufacturers need a real-time process time control system that ensures each stage of production meets the required timing parameters.

The Solution: Automated Process Time Control with camLine MES

camLine MES solution automates process time control, ensuring that every stage in SMT production adheres to defined timing constraints. The system continuously collects process time data, detects violations, and takes immediate corrective action to prevent defective output.

How camLine MES solution optimizes process time control in SMT lines:

- Continuous Monitoring & Data Collection: Tracks process timing across all SMT equipment, ensuring each step is executed within the correct timeframe.

- Real-Time Violation Detection: Detects process time deviations before they lead to quality issues.

- Automated Process Halts: When a violation is detected, the system pauses affected equipment and triggers alerts for corrective action.

- Configurable Timing Parameters: Supports customizable time control settings for different solder paste types, PCB technologies, and process stages.

Ensuring Production Stability with Process Time Control

With camLine MES solution, SMT manufacturers achieve higher production reliability, fewer errors, and optimized process stability—leading to greater yield and cost savings. By implementing camLine MES process time control solution, manufacturers gain:

- Higher Product Quality: Ensures each process step meets precise timing conditions, preventing defects.

- Enhanced Production Efficiency: Reduces delays and improves overall workflow with real-time automation.

- Optimized Resource Utilization: Prevents waste from expired materials by ensuring proper process timing.

- Custom Process Timing Configurations: Enables manufacturers to define unique process timing settings for different product lines and PCB technologies.

With camLine advanced process monitoring, SMT manufacturers can eliminate inefficiencies, improve quality control, and maintain high production throughput.

Subscribe to our newsletter

Get our latest updates and news directly into your inbox. No spam.