Effective Root Cause Analysis in Manufacturing Data

In modern manufacturing environments, systematic quality checks at every production stage are essential for maintaining high standards and minimizing defects. However, when Out-of-Control (OOC) events occur, engineers must analyze SPC charts to determine the root cause. Yet, traditional SPC tools lack access to critical logistics and material history data, making root cause analysis time-consuming and inefficient.

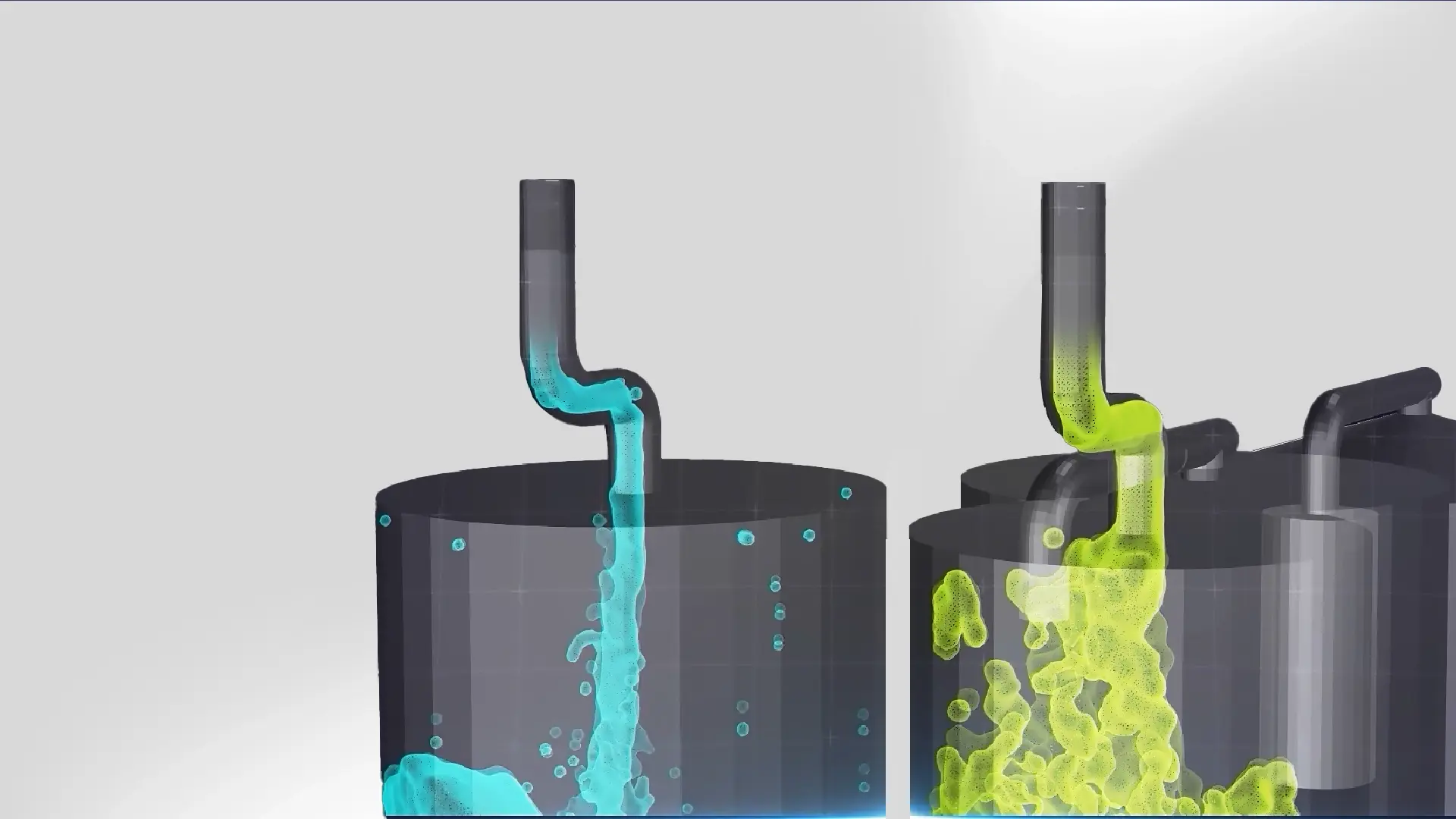

This Work Smarter video introduces LineWorks SPACE Charts Work-in-Progress Plug-ins, a powerful solution that integrates detailed production history into SPC charts, providing deeper insights into process deviations and material traceability.

Effective Root Cause Analysis in Manufacturing Data

In modern manufacturing environments, systematic quality checks at every production stage are essential for maintaining high standards and minimizing defects. However, when Out-of-Control (OOC) events occur, engineers must analyze SPC charts to determine the root cause. Yet, traditional SPC tools lack access to critical logistics and material history data, making root cause analysis time-consuming and inefficient.

This Work Smarter video introduces LineWorks SPACE Charts Work-in-Progress Plug-ins, a powerful solution that integrates detailed production history into SPC charts, providing deeper insights into process deviations and material traceability.

The Challenges: Why Traditional SPC Tools Fall Short in Root Cause Analysis

Manufacturers face several common obstacles when conducting root cause analysis in production environments:

- Limited Data Visibility: Traditional SPC charts display only measured data but lack access to logistics and material traceability.

- Time-Consuming Investigations: Engineers must manually cross-reference production records, slowing down issue resolution.

- Inconsistent Data Across Systems: Quality results and process information are often stored separately, making it difficult to correlate findings.

- Delayed Containment Actions: Without fast access to root cause data, manufacturers risk extended downtimes and higher defect rates.

The Solution: Work-in-Progress (WIP) Plug-in for LineWorks SPACE

LineWorks SPACE WIP Plug-in extends traditional SPC charts to MES-related data, offering a powerful root cause analysis tool that connects material history, process steps, and quality results.

With LineWorks SPACE WIP Plug-in, manufacturers can:

- Link quality data with material traceability, allowing engineers to reference past results down to the exact production step.

- Compare historical production data and track deviations over time for better trend analysis.

- Access logistics data, including material source, purity levels, and tool usage, in a single unified view.

- Accelerate issue containment by quickly pinpointing defective materials and process inconsistencies.

By integrating WIP Plug-in with LineWorks SPACE, manufacturers gain a complete picture of their production workflow, enhancing decision-making and process optimization.

Why Advanced Root Cause Analysis is Essential for Manufacturing

Automating supplier quality management offers multiple advantages, including:

- Faster Issue Identification: Engineers instantly trace defects back to specific process steps.

- Enhanced Process Visibility: Combines quality results with logistics data, eliminating the need for manual searches.

- Reduced Downtime & Scrap: Early detection of defects leads to faster corrective actions and improved yield rates.

- Seamless Integration with SPC Charts: Expands the power of SPC monitoring by enriching analysis with MES insights.

By leveraging LineWorks SPACE WIP Plug-ins, manufacturers gain greater control over production quality, ensuring higher efficiency and fewer disruptions.

Subscribe to our newsletter

Get our latest updates and news directly into your inbox. No spam.