SMART Assist Line Setup in SMT

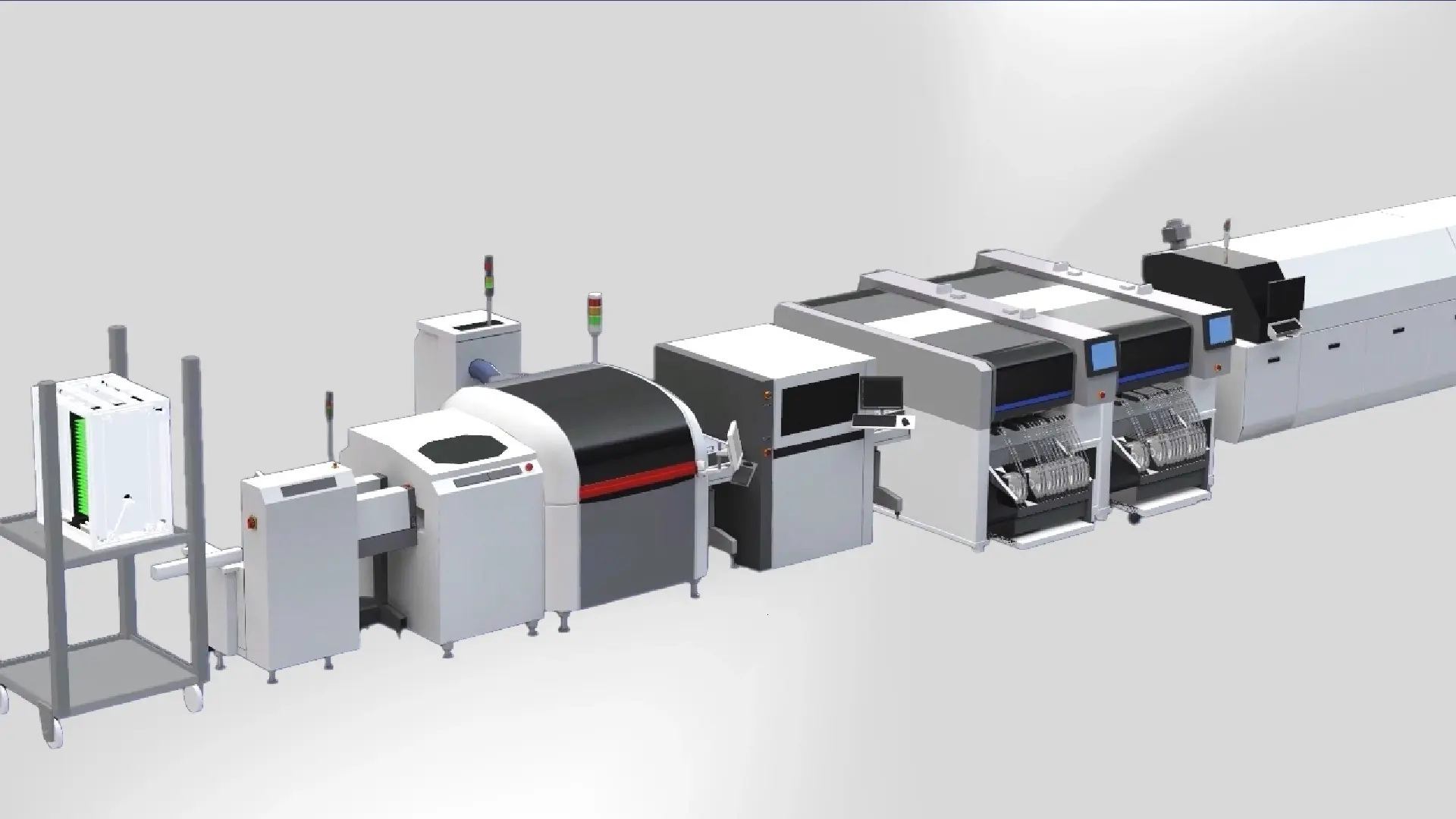

In Surface Mount Technology (SMT) manufacturing, frequent line changeovers are essential to accommodate multiple product types and production lots. However, manual changeovers often result in delays, inefficiencies, and increased rework due to setup errors. Precise, error-free setups are critical to maintaining first-pass yield (FPY) and production efficiency.

In this Work Smarter video, discover how camLine’s SMART Assist Line Setup enhances SMT equipment changeovers with automated material validation, line qualification, and real-time feedback loops—ensuring optimized first-pass yield and minimal setup errors.

SMART Assist Line Setup in SMT Manufacturing

In Surface Mount Technology (SMT) manufacturing, frequent line changeovers are essential to accommodate multiple product types and production lots. However, manual changeovers often result in delays, inefficiencies, and increased rework due to setup errors. Precise, error-free setups are critical to maintaining first-pass yield (FPY) and production efficiency.

In this Work Smarter video, discover how camLine’s SMART Assist Line Setup enhances SMT equipment changeovers with automated material validation, line qualification, and real-time feedback loops—ensuring optimized first-pass yield and minimal setup errors.

The Challenges: Time-Consuming & Error-Prone Line Changeovers

As SMT lines become more complex, manufacturers require a smarter, automated approach to ensure seamless and precise changeovers. Common challenges include:

- Frequent Changeovers Disrupt Efficiency: SMT manufacturers must frequently switch product types, requiring manual coordination, recalibration, and adjustments, leading to delays.

- Manual Setup Errors Lead to Rework: Even minor misplacements of materials or incorrect feeder slots increase defect rates, lowering first-pass yield.

- Limited Automation Slows Setup Validation: Engineers must manually verify the setup, increasing the risk of errors and production bottlenecks.

The Solution: SMART Assist Line Setup

SMART Assist enables fully automated SMT line setup, ensuring real-time validation, reduced setup time, and optimized equipment changeovers. Key features of SMART Assist include:

- Material Setup Validation: Automatically verifies that each component is correctly placed (e.g., reel positions on pick-and-place machines) to reduce errors.

- Automated Line Qualification: Validates the first panel of a batch before full production, pausing for adjustments if issues are detected.

- Real-Time Feedback Loops: Ensures instant alerts on setup errors, allowing for quick corrective actions before defects occur.

- Cascading Changeovers: Supports continuous operations by preparing the next batch setup before the current one is completed.

With SMART Assist, SMT manufacturers can eliminate manual setup inefficiencies and automate validation, reducing downtime and improving production flow.

How SMART Assist Line Setup Improves Production Efficiency

SMART Assist transforms SMT production by integrating AI-driven automation for a smarter, more efficient manufacturing process.

Benefits of Implementing SMART Assist Line Setup:

Higher First-Pass Yield (FPY): Ensures precise setups, reducing defects and rework costs.

Faster Changeovers: Minimizes setup time, enabling seamless batch transitions with less downtime.

Maximized Equipment Utilization: Cascading changeovers optimize machine use, allowing for continuous operation.

Reduced Human Error: Automated validation removes the risk of manual misplacements and recalibration mistakes.

Subscribe to our newsletter

Get our latest updates and news directly into your inbox. No spam.