Achieve Real-Time Visibility with a Transparent SMT Production Line

In Surface Mount Technology (SMT) manufacturing, achieving seamless production planning and control requires a bird’s eye view of your entire operation. Without real-time visibility, manufacturers struggle to track production statuses, equipment conditions, and process flow, leading to inefficiencies, missed production deadlines, and reduced overall performance.

With a centralized view of SMT operations, executives like line supervisors, operation managers, and plant directors can make better-informed decisions, develop effective action plans, and steer production with precision. This Work Smarter video explores how LineWorks MES enables real-time monitoring, improving production efficiency, scheduling, and resource allocation.

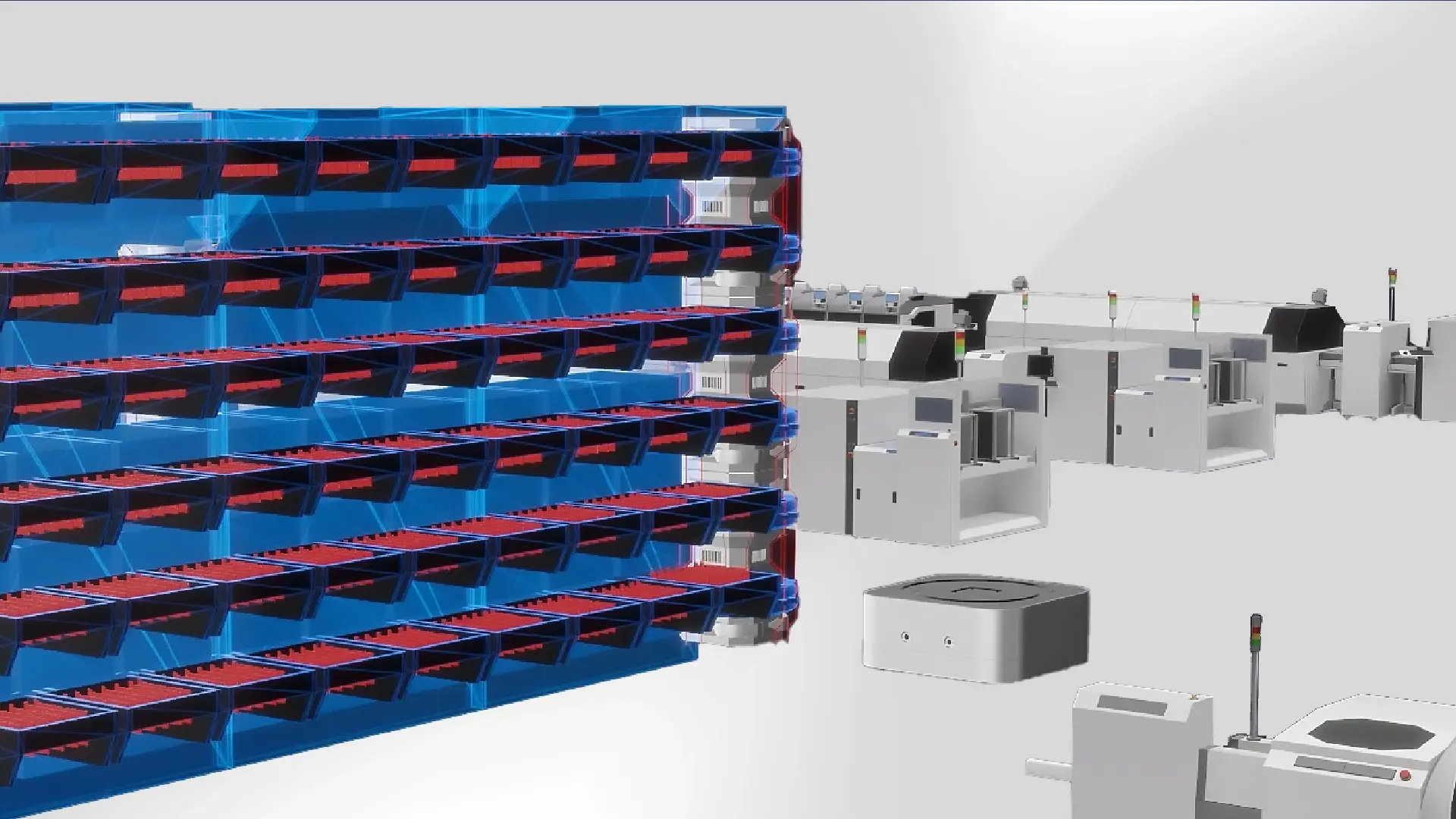

Transparent SMT Production Line Setup

In Surface Mount Technology (SMT) manufacturing, achieving seamless production planning and control requires a bird’s eye view of your entire operation. Without real-time visibility, manufacturers struggle to track production statuses, equipment conditions, and process flow, leading to inefficiencies, missed production deadlines, and reduced overall performance.

With a centralized view of SMT operations, executives like line supervisors, operation managers, and plant directors can make better-informed decisions, develop effective action plans, and steer production with precision. This Work Smarter video explores how LineWorks MES enables real-time monitoring, improving production efficiency, scheduling, and resource allocation.

The Challenges: Lack of Transparency in SMT Lines

Without real-time monitoring, SMT manufacturers lack full production visibility, leading to bottlenecks and inefficiencies. Engineers and plant managers struggle to react promptly to machine downtimes, changeovers, and production delays.

- Bottlenecks & Inefficiencies: Unclear line availability leads to delays in scheduling and resource misallocation.

- Limited Decision-Making: Executives struggle to react quickly to machine downtimes and changeovers.

- Delayed Production Planning: Without live insights, managers cannot optimize production capacity or ensure on-time delivery.

The Solution: Transparent SMT Line Setup with LineWorks MES

A transparent SMT line setup enables manufacturers to gain real-time insights, streamline production planning, and optimize decision-making with live data. LineWorks MES key features include:

- Real-Time SMT Line Monitoring: Gain a bird’s eye view of production—track lot status, line availability, and changeover planning from one interface.

- Optimized Line Utilization: Reduce downtime by identifying the next available line for scheduling.

- Data-Driven Planning: Make informed decisions with real-time equipment alarms, production status, and queue insights.

- Customizable Dashboards: Configure views based on roles, ensuring engineers, supervisors, and plant managers have relevant data for better decisions.

Improved Visibility, Efficiency, and Decision-Making

By implementing camLine’s transparent SMT line setup, manufacturers can realize a wide range of benefits that directly enhance operational efficiency:

- Enhanced Production Planning: Real-time visibility enables accurate scheduling, reducing changeover time and maximizing efficiency.

- Faster Issue Resolution: Instant alerts on equipment status & alarms allow for rapid corrective action, minimizing downtime.

- Data-Driven Decisions: Access live production data to optimize resource allocation, machine utilization, and workflow adjustments.

- Customizable Dashboards: Configure dashboards to display critical insights, empowering teams to respond proactively to production demands.

Subscribe to our newsletter

Get our latest updates and news directly into your inbox. No spam.