What is Digital Transformation?

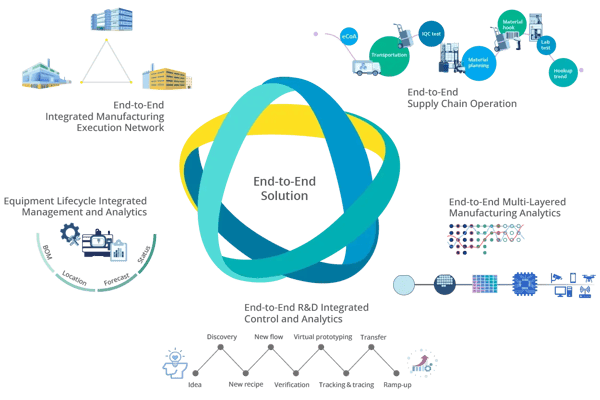

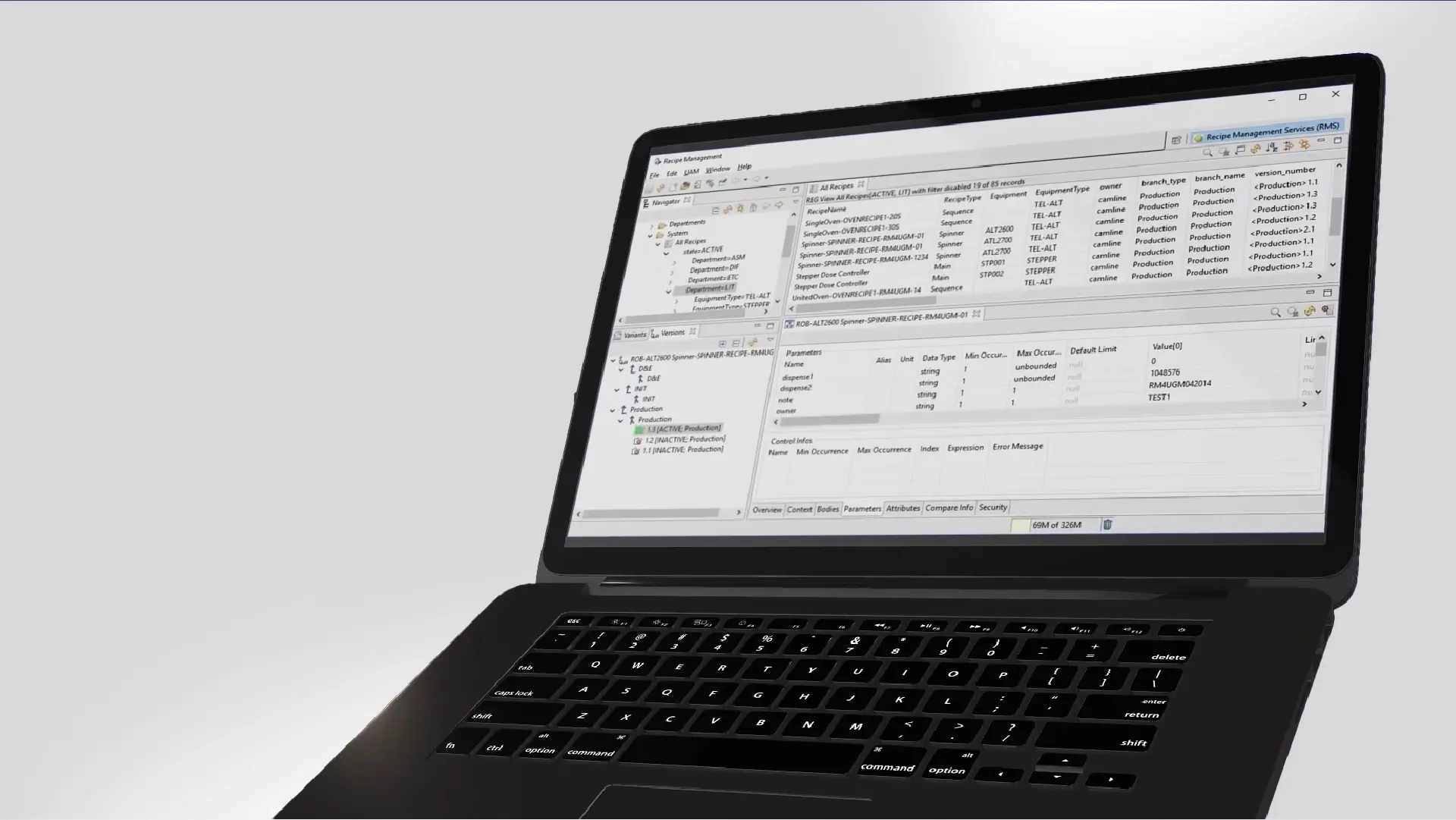

Digital transformation in manufacturing integrates digital technologies across production — from design to delivery. By leveraging data, automation, and analytics, it enables smarter processes, better decisions, and higher efficiency.

Key elements include real-time data insights, connected and automated systems, improved collaboration across departments and supply chains, and tools that optimize resources while supporting sustainability.