Scaling Production to Gigafactory Levels

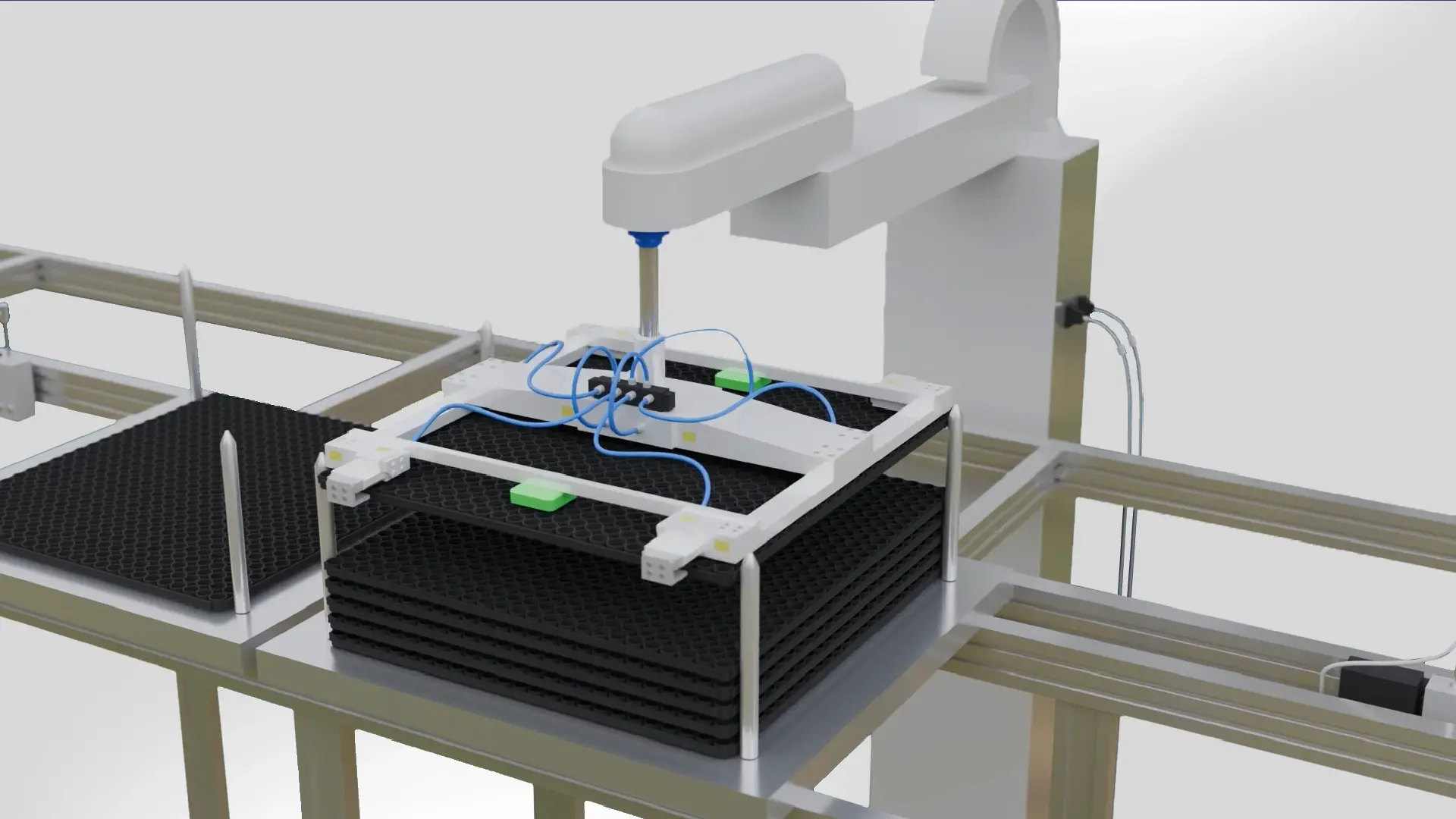

Rapidly increasing production capacity to meet soaring EV battery demand requires robust, scalable manufacturing processes.

Driving battery production excellence with camLine MES Battery Edition through end-to-end visibility, traceability, and adaptable manufacturing control.

The battery manufacturing industry faces increasing challenges due to growing electric vehicle demand, stringent regulations like the battery passport, and the push for sustainable production. Manufacturers must maintain high product quality while managing complex processes across multiple stages—from raw materials to cell assembly and final testing—requiring comprehensive data tracking and traceability throughout the battery lifecycle.

To meet these challenges, camLine tailored MES solutions deliver end-to-end data visibility at every stage of production. By leveraging advanced operational intelligence, camLine empowers battery manufacturers to accelerate ramp-ups, detect anomalies early, improve yield, ensure compliance, and drive continuous improvement in this fast-evolving sector.

Challenges

Rapidly increasing production capacity to meet soaring EV battery demand requires robust, scalable manufacturing processes.

Manufacturers must handle diverse battery chemistries and formats, requiring flexible production lines that support different technologies efficiently.

Supply constraints and complex production stages demand precise material tracking and coordination to avoid bottlenecks and quality issues.

Tight schedules to launch new products and ramp-up production necessitate agile manufacturing systems to stay competitive.

Meeting stringent regulations, including battery lifecycle management and recycling mandates, is critical for market access and sustainability goals.

High-quality standards and consistent yields must be sustained despite increased production volumes and process complexities.

How we help

Our MES software is built to address the complexities of battery manufacturing. It provides real-time monitoring, detailed reporting, end-to-end visibility, and precise control across multi-stage processes — from raw material handling to cell assembly and final testing.

Who we help

We support leading battery manufacturers with MES solutions tailored to manage complex production workflows, ensure product quality, and maintain full traceability across the battery lifecycle.

Our solutions assist manufacturers assembling battery modules and packs by providing end-to-end visibility, streamlining production coordination, and enhancing battery management system integration.

We enable raw material and active component suppliers to maintain strict quality standards through integrated supplier quality management, traceability, and early risk detection, reducing supply chain disruptions and supporting sustainable battery production.

Our software integrates seamlessly with diverse production machinery and equipment providers, facilitating real-time data exchange, improved equipment utilization, and smooth production flow without vendor lock-in.

In this Work Smarter video, camLine introduces a scalable and flexible AI-driven solution—Battery Lifetime Predictor and Root Cause Analyzer—designed to help battery manufacturers significantly reduce R&D testing times and enhance overall battery manufacturing quality.

In this Work Smarter video, camLine introduces a scalable and flexible AI-driven solution—Battery Lifetime Predictor and Root Cause Analyzer—designed to help battery manufacturers significantly reduce R&D testing times and enhance overall battery manufacturing quality.

camLine MES Battery Edition supports all production user groups—from process and plant engineers to production managers and operators—enhancing process control, ensuring high-quality output, and driving operational excellence across teams.

Explore our resource library to discover how camLine supports high-tech manufacturers in enhancing quality, efficiency, and reliability.

Discover how theion and camLine reduced battery R&D testing time from 42 days to 15 hours using AI-Driven predictive models data analysis.

Streamline the transition from lab to production with a flexible simulator. Simulate scenarios, calculate costs, and optimize processes for excellence.

Discover how Axetris transformed semiconductor production by digitizing with MES—boosting efficiency, reducing errors, and enhancing traceability.

Learn how STMicroelectronics improves shopfloor analysis and anomaly detection with ML-driven advanced SPC solutions for better process control.

We believe successful software implementation requires more than great technology—it needs people who understand your business. Our co-development model with industry leaders ensures solutions address real-world challenges.

Why choose us

As your partner, we provide quality-driven MES/MOM solutions that transform data into a competitive advantage for high-tech industries.

Trusted by over 350 customers worldwide across various high-tech industries.

Empower manufacturers to achieve growth and excellence in over 40 countries globally.

Delivering proven manufacturing software solutions, from single-site pilots to global multi-site rollouts.

Modular MES systems with flexible modules that can be deployed step by step and expanded as operations grow.

Tailored MES/MOM solutions for different industries including solar, battery, semiconductor, and medical device.

Serving as the foundation of camLine MES, LineWorks SPACE supports quality assurance and advanced process control.

Our team is ready to deliver tailored solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.