Complex and Frequent Line Changeovers

Electronics manufacturing lines manage diverse product types requiring rapid, error-free setup and material validation to maintain first-pass yield and minimize downtime.

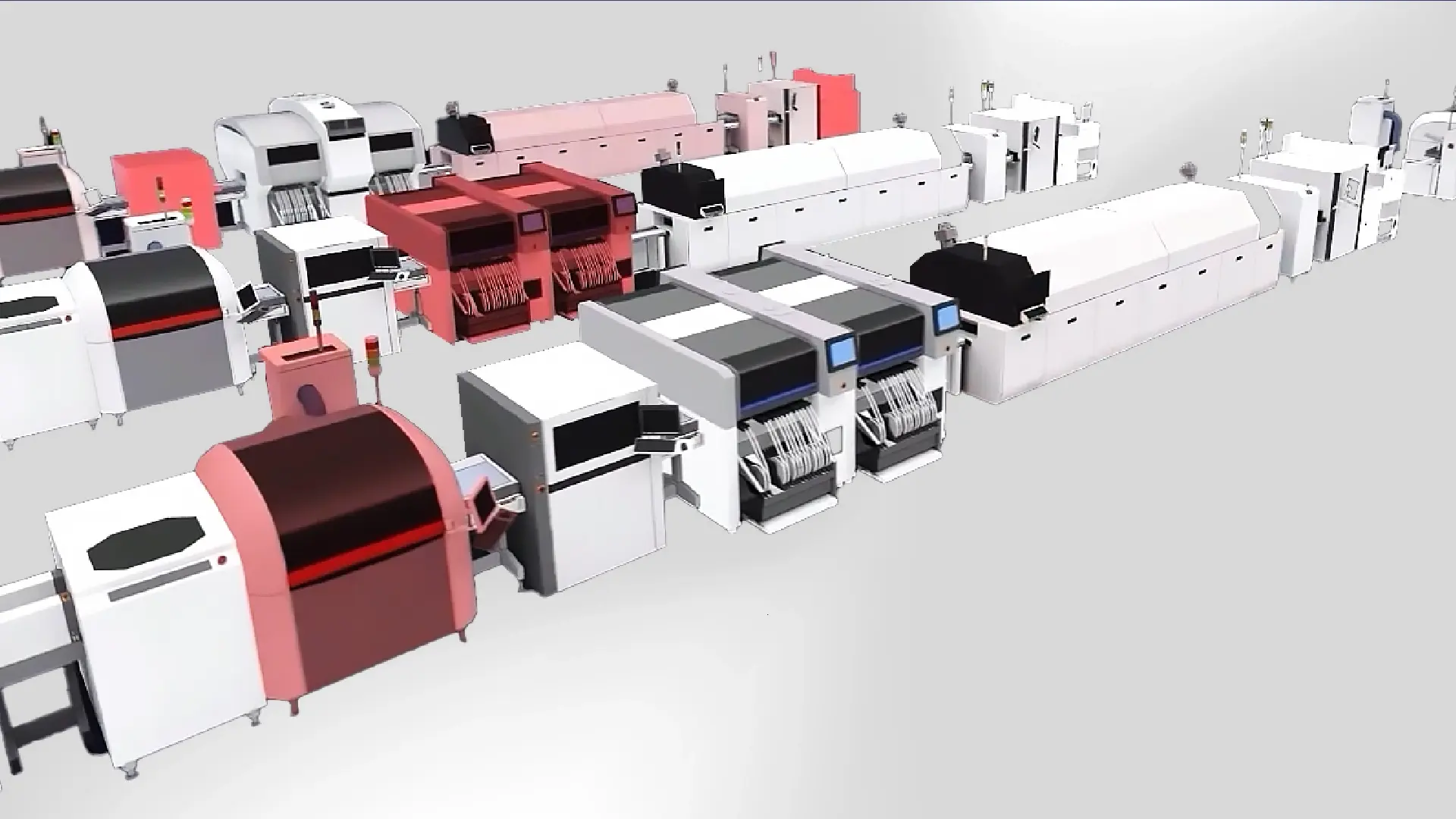

Optimizing electronics production with camLine MES software for precise control, end-to-end traceability, and efficiency at every stage of your manufacturing process.

Electronics manufacturing requires precision, speed, and seamless coordination across complex assembly lines, including SMT, through-hole, and testing. Accurate data capture and real-time process control are essential at every stage to maintain quality and throughput. camLine’s tailored MES solutions deliver end-to-end visibility, streamline material flow, and support agile production adjustments, ensuring electronics manufacturers increase first-pass yield, reduce rework, and consistently meet delivery deadlines.

Challenges

Electronics manufacturing lines manage diverse product types requiring rapid, error-free setup and material validation to maintain first-pass yield and minimize downtime.

Managing hundreds of components with specific handling and validity requirements demands precise, real-time inventory tracking to prevent production stoppages and excess waste.

Maintaining strict control over process parameters and timing is essential to ensure quality and avoid defects caused by deviations in solder paste application, component placement, or reflow cycles.

Lack of transparent, real-time monitoring across the entire SMT line causes delays in detecting issues, bottlenecks, and inefficient resource allocation.

SMT lines often include machines from multiple suppliers, posing challenges to seamless integration, data sharing, and centralized control without vendor lock-in.

Disconnected data sources and reliance on manual processes hinder proactive quality control and timely corrective actions.

How we help

Our MES capabilities are designed to meet the specific needs of electronics production, providing tools that enhance visibility, control, and efficiency at every stage of your manufacturing process.

Who we help

We enable OEMs to maintain consistent process quality and streamline technology transfer across multiple production sites with unified MES solutions.

We support EMS providers with real-time monitoring, flexible recipe management, and process control to handle diverse customer requirements and production runs efficiently.

We help CMs manage frequent product changes and ensure quality compliance with advanced MES software delivering end-to-end traceability and full visibility across complex electronics production chains.

Accurate, real-time inventory tracking ensures uninterrupted SMT production and minimizes waste. In this Work Smarter video, discover how camLine’s MES solutions enable just-in-time material availability and optimize inventory management for efficient operations.

Accurate, real-time inventory tracking ensures uninterrupted SMT production and minimizes waste. In this Work Smarter video, discover how camLine’s MES solutions enable just-in-time material availability and optimize inventory management for efficient operations.

Ready to explore how the Line Controller can transform your SMT operations? Speak directly with us to learn how camLine’s innovative software solutions can be tailored to meet the specific needs of your manufacturing environment.

Explore our resource library to discover how camLine supports high-tech manufacturers in enhancing quality, efficiency, and reliability.

Discover how B. Braun leverages camLine’s InFrame Synapse MES to enhance medical device manufacturing and achieve operational excellence.

Discover how Axetris transformed semiconductor production by digitizing with MES—boosting efficiency, reducing errors, and enhancing traceability.

Learn how STMicroelectronics improves shopfloor analysis and anomaly detection with ML-driven advanced SPC solutions for better process control.

Learn how Intel and camLine collaborate to enhance factory automation, improve system integration, and drive operational efficiency in manufacturing.

We believe successful software implementation requires more than great technology—it needs people who understand your business. Our co-development model with industry leaders ensures solutions address real-world challenges.

As your partner, we provide quality-driven MES/MOM solutions that transform data into a competitive advantage for high-tech industries.

Trusted by over 350 customers worldwide across various high-tech industries.

Empower manufacturers to achieve growth and excellence in over 40 countries globally.

Delivering proven manufacturing software solutions, from single-site pilots to global multi-site rollouts.

Modular MES systems with flexible modules that can be deployed step by step and expanded as operations grow.

Tailored MES/MOM solutions for different industries including solar, battery, semiconductor, and medical device.

Serving as the foundation of camLine MES, LineWorks SPACE supports quality assurance and advanced process control.

Our team is ready to deliver tailored solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.