Rapid Problem Resolution

Achieve fast, precise resolutions through real-time, automated decision-making.

Operational excellence through fully integrated corrective actions on SPC violations.

LineWorks SPACE eCAP extends LineWorks SPACE by integrating an Electronic Corrective Action Plan (eCAP) to automate workflows and streamline quality assurance and compliance management. As an add-on module, LineWorks SPACE eCAP enables process experts to define, refine, and execute corrective actions (CAs) directly within the operational environment. This ensures compliance with quality standards and your organization’s specific process requirements while improving efficiency and traceability.

.png?width=149&height=100&name=Logos_ams-20250829-092441%20(1).png)

Streamline issue resolution, minimize human error, and drive continuous process improvement with intelligent automation.

Achieve fast, precise resolutions through real-time, automated decision-making.

Full audit trails with complete records of all actions ensure improved compliance.

Automated workflows with escalation strategies minimize manual intervention.

Best-practice procedures to guide operators step-by-step.

Easily implement fully and semi-automated workflows across the manufacturing value stream.

Gain valuable insights with a historical record of corrective actions and outcomes.

Simplify deployment without the need for manufacturing IT support.

Ensure consistent, reliable operations.

The latest release of LineWorks SPACE eCAP, version 3.3.4, introduces a modernized, responsive interface that aligns with LineWorks iGate 4, optimizing usability across all devices, including mobile platforms. This update makes it easier to access eCAP instances on any platform.

The latest release of LineWorks SPACE eCAP, version 3.3.4, introduces a modernized, responsive interface that aligns with LineWorks iGate 4, optimizing usability across all devices, including mobile platforms. This update makes it easier to access eCAP instances on any platform.

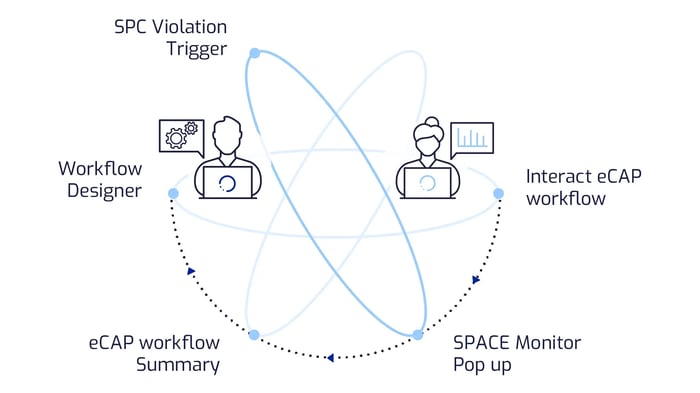

LineWorks SPACE eCAP delivers a structured approach to managing SPC violations by automating workflow execution and ensuring corrective actions are properly tracked. When a violation occurs, the system triggers an interactive workflow, providing real-time monitoring, clear visualizations, and seamless integration with LineWorks SPACE Charts. With an intuitive workflow designer, process experts can define corrective measures without programming knowledge, ensuring compliance and efficiency in manufacturing operations.

SPC violations in LineWorks SPACE will initiate the workflow.

Operational activities required to complete the detailed workflow.

SPACE Chart visualization when needed in the workflow.

All completed workflows are linked to SPACE Charts.

Create interactive workflows without programming knowledge.

Automated workflows, real-time monitoring, and seamless SPC integration.

Responds to SPC violations through configurable rules and expressions, ensuring timely corrective actions based on real-time data.

A user-friendly, code-free interface for creating and customizing corrective action workflows.

Provides a web-based dashboard for operators to monitor corrective actions and overall workflow progress.

Accessible from any device, allowing operators to execute corrective actions efficiently within the operational environment.

Guides operators through corrective actions, promoting consistent and accurate responses.

Enables easy access to measurement data, facilitating validation and troubleshooting directly within the system.

Seamlessly links corrective actions to Out-of-Control (OOC) points in LineWorks SPACE Charts for immediate response to process deviations.

Achieve process integrity and compliance with LineWorks SPACE eCAP by seamlessly managing SPC violations through structured corrective action (CA) workflows.

Explore our resource library to discover how camLine supports high-tech manufacturers in enhancing quality, efficiency, and reliability.

Discover how B. Braun leverages camLine’s InFrame Synapse MES to enhance medical device manufacturing and achieve operational excellence.

Discover how theion and camLine reduced battery R&D testing time from 42 days to 15 hours using AI-Driven predictive models data analysis.

Discover how Axetris transformed semiconductor production by digitizing with MES—boosting efficiency, reducing errors, and enhancing traceability.

Learn how STMicroelectronics improves shopfloor analysis and anomaly detection with ML-driven advanced SPC solutions for better process control.

Our team is ready to deliver tailored MES solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.