Raw and Statistical Data Collection

Sample Size and Screen Values Control: The system can support data collection with fixed sample size control, screen values entry control, and comprehensive validation capabilities.

LineWorks SPISE++ is a comprehensive web-based solution designed specifically to simplify and enhance data collection processes in high-tech manufacturing environments. Built to seamlessly integrate with LineWorks SPACE, it empowers engineers to design data collection interfaces, enabling operators to capture data efficiently for statistical process control. LineWorks SPISE++ also supports features such as data grouping and automated charting for LineWorks SPACE, minimizing manual effort and errors.

.png?width=149&height=100&name=Logos_ams-20250829-092441%20(1).png)

.png?width=303&height=100&name=Logos_azur%20space-20250829-092549%20(1).png)

LineWorks SPISE++ operates on the principle of providing a user-friendly, web-based data input environment that allows engineers to design tailored interfaces without the need for extensive programming.

The platform leverages context automation, integrating directly with MES (Manufacturing Execution Systems) to auto-fill critical context information. This setup minimizes manual entry and enables efficient, rule-compliant data capture, directly feeding validated data into LineWorks SPACE for further analysis.

Highlights of Release 5.0:

Key features

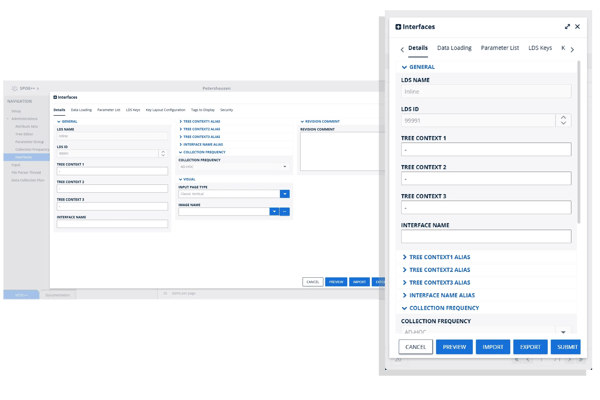

LineWorks SPISE++ offers a streamlined approach to data collection, making it highly efficient for operators without requiring extensive programming skills. This configurable automatized procedure for web-based input interfaces allows SPC administrators to effortlessly define rich context information for each data collection interface, ensuring all context keys are synchronized with the SPACE LDS setup.

Able to adapt well on all devices, whether viewed from a desktop, tablet, or smartphone, the design prioritizes accessibility and functionality.

Administrators can seamlessly design and configure the context key interface, allowing operators to efficiently compile relevant context information for each data collection process.

SPISE++ auto fill context data by synchronizing with MES and other systems, minimizing the operator’s workload and ensuring data consistency across different collection interface.

Supports multiple data types—including raw, attribute, and calculated parameters—ensuring comprehensive data collection. Operators can access SPC charts directly from the input page, eliminating the need for manual searches. Additionally, the system integrates barcode scanning for quick and accurate data entry, while alias naming allows administrators to customize interface labels across multiple languages, improving collaboration in multilingual environments.

LineWorks SPISE + + supports various collection parameters definition options, including raw data, statistical data, attribute data, external calculated parameters, advance alert parameter, and parsed sample setup, providing comprehensive support for different data collection needs.

Sample Size and Screen Values Control: The system can support data collection with fixed sample size control, screen values entry control, and comprehensive validation capabilities.

Flexible Calculation Method: The system offers a flexible calculation method, supporting freely configurable calculations for a given data collection plan, whether it operates in manual, semi-automatic, or fully automatic mode.

Data Validation: This type of parameter retains a similar purpose to calculated parameter, designed to validate the operator’s data input and ensure it meets the user’s requirement.

Enhance Fixed File Parser Configuration: A special parameter designed not for data collection but to enable additional configurations. Provides the definition of sub-grouping, external specification limits, and external control limits for enhanced functionality of the fixed file parser.

Attribute Set Management and Hot Key Assignment: LineWorks SPISE + + enables efficient and streamlined management of attribute data sets and hot key assignments. This solution also reduces operator data collection effort and enhances control chart capabilities through automated attribute grouping functionality.

With built-in automation features, LineWorks SPISE++ enhances the efficiency of data entry and collection processes, reducing the need for manual intervention.

The system can import data directly from applications like Excel and Notepad or even query and auto-populate key information with the MES query plugin, minimizing the number of key strokes for the data entry process.

Automated input from equipment such as microscopes, Automated Optical Inspection (AOI) machines, and serial port devices ensures accurate, real-time data streaming into the system.

LineWorks SPISE++ includes a frequency management controller that tracks data collection timing. Administrators can set up flexible schedules with options for fixed or dynamic intervals, ensuring timely data submission.

The system supports automated data grouping, flagging, and SPC chart generation, allowing for easier analysis and quick identification of trends

LineWorks SPISE++ offers a comprehensive, flexible, and highly automated platform for data collection, directly integrated with LineWorks SPACE. By reducing manual input and enhancing process efficiency, SPISE++ empowers manufacturers to maintain high standards of data quality and process control.

Capabilities

Automatically groups data based on predefined parameters, enabling more efficient analysis and control. Flagging options help streamline quality checks and reduce the need for manual audits.

Automates the creation of SPC channels and chart, simplifying the visualization of collected data.

Automates the addition of sample tags to indicate special events.

Provides capabilities for analyzing multiple parameters, such as wafer-site mean, wafer mean, and lot mean calculations, giving deeper insights into process performance

Monitors the running loaders, making sure that all loaders run as expected.

Provides the ability for third-party applications to access SPISE++ functions through a RESTful call.

Benefits

Streamline data entry with LineWorks SPISE++, a user-friendly web-based interface—no coding required. Automate context data with MES integration for seamless, rule-compliant capture.

Explore our resource library to discover how camLine supports high-tech manufacturers in enhancing quality, efficiency, and reliability.

Discover how B. Braun leverages camLine’s InFrame Synapse MES to enhance medical device manufacturing and achieve operational excellence.

Discover how theion and camLine reduced battery R&D testing time from 42 days to 15 hours using AI-Driven predictive models data analysis.

Discover how Axetris transformed semiconductor production by digitizing with MES—boosting efficiency, reducing errors, and enhancing traceability.

Learn how STMicroelectronics improves shopfloor analysis and anomaly detection with ML-driven advanced SPC solutions for better process control.

Our team is ready to deliver tailored MES solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.