Mastering food and beverage supply chain efficiency

This article guides you through F&B supply chains: practical methods to reduce waste, increase production efficiency, and meet regulatory requirements.

Key takeaways:

- Use FEFO planning (first-expired, first-out) to reduce waste from expired products

- Improve production line changeovers and add quality checks into your production schedule

- Build tracking systems that follow products from start to finish for faster recalls and easier audits

- Reduce waste by improving how you use logistics, energy, and packaging

- Use connected systems to see and control the balance between service quality, costs, and compliance

- Enhance the sales forecasting workflow by leveraging advanced AI and machine learning models to optimize raw material requirements planning, with a specific focus on managing seasonal materials

The food and beverage industry faces a constant tension: balancing perishability, safety requirements, margin pressure, and cost. Food waste across supply chains remains one of the biggest efficiency challenges in the industry, with massive amounts of food lost between production and consumption.

This article shows how to build a resilient and compliant supply chain using integrated systems so that you can make better decisions for planning, production, efficiency, and traceability.

Understanding the food & beverage supply chain

Food and beverage supply chains face different challenges than other manufacturing sectors. Two main factors create these challenges: perishability and compliance requirements.

While discrete manufacturers such as automotives can handle unexpected changes by keeping extra inventory, F&B leaders race against the clock due to the perishability of raw materials. For example, fresh pasta, or fresh filled pasta can be stored for 1-2 days, while canned goods may last months or years. However, stores often only accept products if they still have enough shelf life left (for example, at least 9 months remaining on a 12-month product). The raw materials for canned goods (vegetables, tomatoes) spoil quickly and must be processed immediately, which creates limits for production scheduling.

When ingredients expire, they must be discarded, and this wastage has not just an environmental impact, but also a financial one, directly impacting profitability.

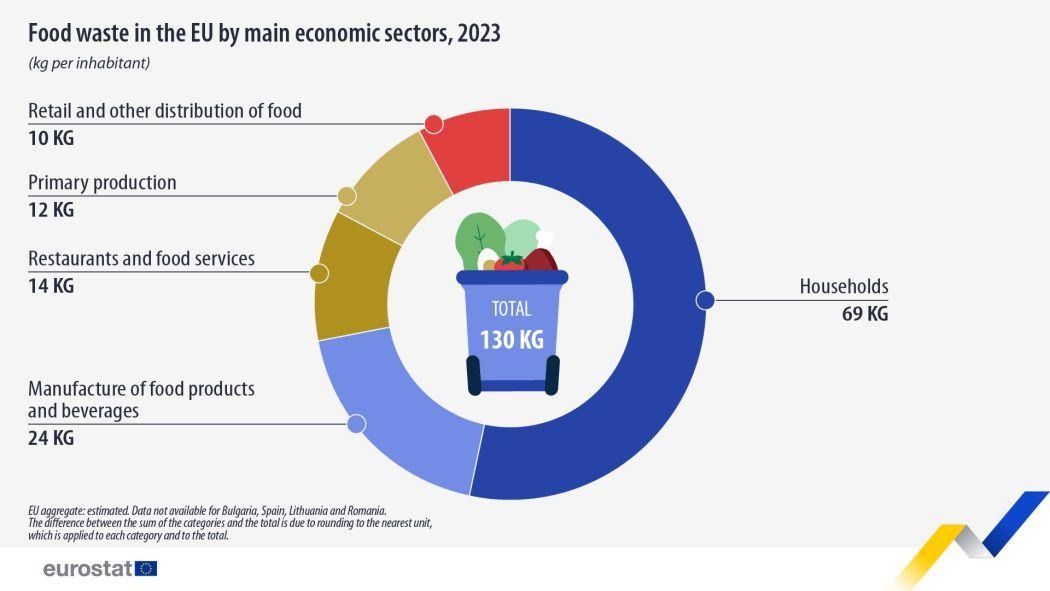

In 2023, the EU generated 58.2 million tonnes of food waste, approximately 130 kg per person (Eurostat, 2025):

Households generate more than half of all food waste in the EU, accounting for 69 kg per person annually. The manufacturing and food service sectors contribute the remaining waste across the supply chain.

Compliance adds an additional layer of complexity. Regulations like the EU's Corporate Sustainability Reporting Directive (CSRD) and the EU General Food Law (Regulation EC 178/2002) require detailed tracking and reporting. These requirements improve transparency and enable faster responses to problems in supply chains.

Meanwhile, external factors add further unpredictability. In 2025, supply chains aren't failing in the traditional sense where products cannot be delivered at all, but they encounter capacity limits and bottlenecks more frequently due to erratic weather patterns, crop failures, geopolitical disruptions, and shifting trade policies.

These pressures can force manufacturers to make trade-offs between service levels, cost control, and waste reduction.

- Good service levels require fast production to keep products on shelves

- Lower costs come from longer production runs and larger batches

- Less waste requires tight control of expiry dates and precise tracking

For instance, maintaining higher inventory buffers to ensure service levels increases the risk of wastage for perishable items. Similarly, aggressive cost-cutting in transportation or packaging can compromise product safety and freshness, damaging consumer trust.

The key lies in making these trade-offs visible and manageable through integrated planning and execution systems. Siloed systems create blind spots where planners can’t see perishability risks and quality issues aren’t prevented early in the process.

A unified platform makes these trade-offs visible and manageable.

For example, Campari Group implemented sedApta's Shop Floor Monitor, Suite O.S.A. Analytics, and Communication Manager across its bottling operations to gain real-time visibility into production performance. Communication Manager enables the system to connect with machines from different suppliers and integrate equipment of various generations into one platform. The Shop Floor Monitor tracks machine downtimes and shows which types of stops have the biggest impact on efficiency. The system monitors input material quality (such as bottle defects) and connects them to specific supplier batches, making it easier to identify and solve quality problems quickly. Suite O.S.A. Analytics tracks key process parameters automatically and provides accurate production data by monitoring waste as products move between machines. This visibility helps production managers calculate OEE accurately and focus improvement efforts where they matter most.

Pedon, an Italian company that produces shelf-stable ready meals from legumes, grains, and vegetables, chose sedApta for its unified platform approach. The company processes highly perishable raw materials (fresh vegetables, mushrooms) into ready-to-eat products with 18-month shelf life. Rather than using separate systems for different functions, Pedon selected a complete suite of modules that can be turned on over time. This structure lets the company build a complete solution step by step, adding new features as business needs change, while keeping all manufacturing operations connected in one system.

Planning for freshness: FEFO and shelf-life across the network

In a sector where products have a built-in expiration date, time is your most critical metric for efficiency. Moving from a passive First-In, First-Out (FIFO) approach to a proactive First-Expired, First-Out (FEFO) system is a foundational shift.

FIFO moves the oldest stock based on its arrival date. FEFO prioritises products with the nearest expiration dates, regardless of arrival. This distinction is crucial: FEFO prevents short-dated lots from being trapped behind fresher stock, significantly reducing write-offs and improving the freshness that reaches consumers.

The implementation challenge is system integration. FIFO logic is the default in many systems, but FEFO requires proper configuration of ERP and WMS (Warehouse Management System) solutions. Companies that adopt FEFO logic report not just lower waste, but also improved compliance scores during audits.

An effective plan must define not just total shelf life, but also the minimum remaining shelf life (MRSL) required by your retail partners.

For example, if milk has a 21-day shelf life but a retailer requires 10 days of remaining life for sale, your planning must reserve only the first 11 days for transit and distribution. Failure to account for this buffer means products arrive at retail with insufficient freshness, leading to rejections or costly markdowns.

FEFO logic applies to raw materials as well as finished products. However, for raw materials, using FEFO alone is often not enough. Real improvement comes from optimizing ingredient utilization and selecting the most appropriate production formula to minimize the risk of ingredients expiring without affecting product quality.

For example, if you have tomatoes that will expire in 2 days and mushrooms that will expire in 5 days, your production planning should prioritize recipes that use tomatoes first, or adjust formula quantities to consume ingredients before they spoil. This approach requires your planning system to consider ingredient expiry dates when deciding which products to manufacture and which recipe variations to use.

From plan to plant: optimising the food manufacturing supply chain

Translating freshness and quality goals into executable production plans requires manufacturing operations that are both highly efficient and agile.

Changeover optimisation without compromising quality

In food manufacturing, changeovers involve cleaning and quality checks. For example, a plant that manufactures ready-to-eat meals might analyse that from its 75-minute changeover, 27 minutes are spent on cleaning.

By pre-staging protocols and partially pre-cleaning equipment while the line was still running, internal changeover time could be cut down to 45 minutes, freeing up 8-10 hours of production capacity weekly.

Integrated quality management inside production schedules

Instead of treating quality as a separate function, you can embed it directly into production schedules. Modern MES solutions can enforce quality checks and document results automatically.

Such AI-driven workflows can detect assembly line issues in real time and identify the root cause, automatically adapting workflows according to these insights.

This focus on Right-First-Time (RFT) production can reduce scrap rates by preventing defects rather than catching them later. In complex manufacturing with many process steps, defects often go unnoticed until final inspection. Modern MES-systems prevent this by embedding quality controls directly into each production stage.

Coordinating freshness policies between suppliers and plants

Extend your freshness management upstream. Define and communicate minimum remaining shelf life (MRSL) requirements to your suppliers.

Shared visibility platforms allow for aligned production and logistics, reducing material waste by ensuring raw materials arrive with adequate shelf life. Supplier scorecards that track freshness performance create accountability and continuous improvement.

Scheduling production efficiently for mixed SKUs

Plants that produce multiple product variants (mixed-SKU environments) juggle flavours, sizes, recipes, and more. Advanced scheduling algorithms can sequence production to minimise changeovers while ensuring products with the shortest shelf lives are manufactured closest to their shipment dates.

Optimizing usage of ingredients through formula flexibility

Planning systems can optimize how you use ingredients by selecting different production formulas that keep the same quality level while using raw materials before they expire. For example, if you produce tomato sauce and have tomato paste that will expire in 3 days, the system can recommend switching to a formula that uses more tomato paste and less fresh tomatoes, as long as both recipes meet the same quality standards.

Optimization algorithms and AI systems check which formula options to use based on your current ingredient stock and expiry dates. This changes ingredient management from reacting to problems (throwing away expired materials) to planning ahead (producing items that use materials before they expire). The result is less waste without affecting product quality or consistency.

Traceability you can trust: end-to-end visibility for recalls and audits

Modern traceability systems use digital tools to capture and store data at every step of the supply chain, from raw material receipt through processing, packaging, to transit conditions.

The EU General Food Law requires detailed tracking across the supply chain, signaling a broader shift toward digital traceability and proactive risk prevention. Companies handling high-risk items must maintain detailed traceability data, including assigning lot codes (unique identifiers for each production batch) and tracking critical tracking events.

The global food traceability market is growing rapidly, driven by regulatory requirements. Technologies like RFID tags (wireless tracking chips), QR codes, and blockchain (secure digital record systems) are increasingly used across supply chains to track products and verify their origin.

Lot genealogy means that if a raw material is contaminated, you can instantly identify every finished product that contains it, all the way to the customer.

Companies with complete genealogy can execute precise recalls in days, while those relying on manual spreadsheets can take weeks, during which unsafe products may remain on shelves.

Every movement and transformation should generate a digital event: receiving materials, processing, packaging, quality release, and shipping. In MES, traceability is a core capability that enables root-cause analysis and supports compliance.

You should conduct regular mock recalls (practice exercises that test your recall procedures) to test your system’s ability to trace products from source to customer, and implement systems that monitor not just your immediate suppliers but also deeper supplier tiers.

Building sustainable and resilient networks for beverages and perishables

The global food system accounts for approximately one-third of all greenhouse gas emissions and 70% of freshwater use. For beverage and perishable food companies, building sustainable supply chains isn't just an environmental necessity, it's becoming essential for business resilience, regulatory compliance, and meeting consumer expectations.

Modern consumers increasingly demand transparency about where their food comes from and how it's produced. Meanwhile, climate change threatens traditional supply chains with extreme weather events, water scarcity, and shifting agricultural zones. Companies that fail to adapt risk supply disruptions, reputational damage, and losing market share to more sustainable competitors.

Three pillars of sustainable food networks

Successful sustainability transformation in food and beverage rests on three interconnected pillars:

1. Resource efficiency: Minimizing waste, water, and energy use across operations

2. Supply chain resilience: Building networks that can withstand climate and market shocks

3. Measurable impact: Tracking and reporting progress with credible metrics

Some key strategies for transformation

1. Redesigning distribution for minimal environmental impact

Temperature-controlled supply chains for beverages and perishables consume enormous amounts of energy. Companies are revolutionizing these networks through:

- Smart cold chain optimization using IoT sensors and AI to maintain quality while minimizing energy use

- Localized distribution hubs that reduce transportation distance

- Alternative refrigeration technologies including natural refrigerants and solar-powered cooling

2. Creating circular systems that eliminate waste

Food waste represents both an environmental disaster and a massive economic loss. Leading companies are implementing:

- Predictive analytics to match supply with demand more accurately

- Upcycling programs that transform food byproducts into new revenue streams

- Packaging innovations using biodegradable materials and refillable systems

3. Building transparency and accountability

Stakeholders demand proof of sustainability claims. Companies must:

- Implement comprehensive tracking from farm to consumer

- Adopt recognized standards like Science Based Targets and B Corp certification

- Report progress transparently using frameworks like TCFD and GRI

The path forward

The UN's Sustainable Development Goals set a 2030 deadline for halving food waste and achieving responsible production. Meeting these targets requires immediate action. Forward-thinking companies are already discovering that sustainable practices often reduce costs, open new markets, and strengthen brand loyalty.

For beverage and perishable food companies, the question is no longer whether to pursue sustainability, but how quickly they can transform their networks to thrive in a resource-constrained future.

Conclusion

Mastering food and beverage supply chain efficiency requires an integrated approach that connects planning, production, traceability, and sustainability into a cohesive whole. By implementing freshness planning, optimising manufacturing changeovers, building robust traceability, and designing sustainable networks, F&B companies can simultaneously advance service, cost, waste, and compliance objectives.

Ready to take the first step?

If you're evaluating how a modular approach might apply to your specific environment, request an architecture assessment with our technical team. We'll review your current landscape, identify highest-value starting points, and outline a realistic implementation pathway, no commitment required.

Subscribe to our newsletter

Get our latest updates and news directly into your inbox. No spam.