Expedite Battery R&D Cycle with AI-Powered Battery Lifetime Predictor and Root Cause Analyzer

The global push toward net zero emissions is driving rapid growth in electric vehicle (EV) adoption. As demand for EV batteries rises, manufacturers face increasing pressure to accelerate production while maintaining strict quality standards.

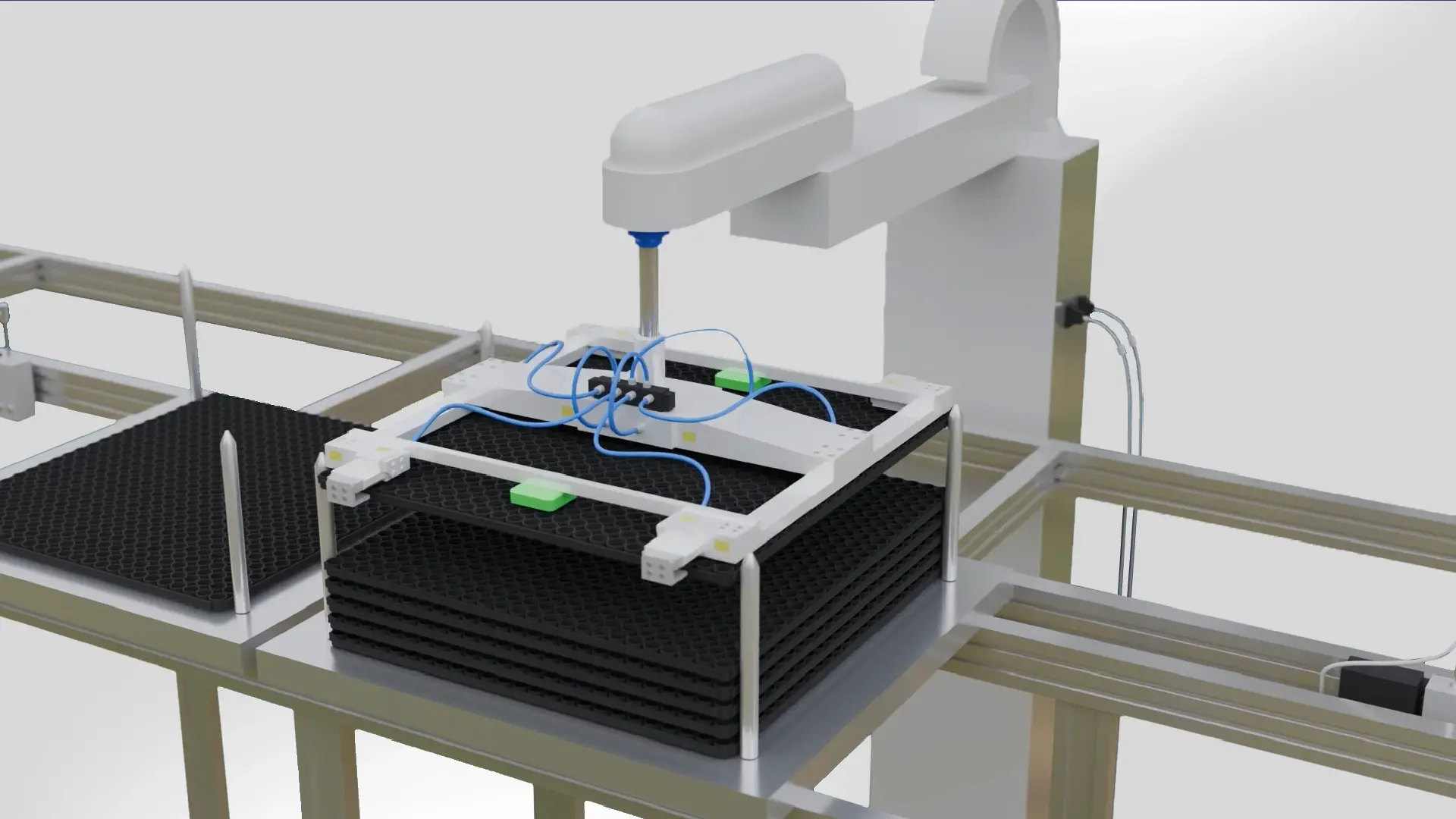

In this Work Smarter video, camLine introduces a scalable and flexible AI-driven solution—Battery Lifetime Predictor and Root Cause Analyzer—designed to help battery manufacturers significantly reduce R&D testing times and enhance overall battery manufacturing quality. This solution is also available as a Software as a Service (SaaS) model for faster, more flexible adoption that aligns seamlessly with evolving business demands.

AI-Driven Solution for Battery R&D

The global push toward net zero emissions is driving rapid growth in electric vehicle (EV) adoption. As demand for EV batteries rises, manufacturers face increasing pressure to accelerate production while maintaining strict quality standards.

In this Work Smarter video, camLine introduces a scalable and flexible AI-driven solution—Battery Lifetime Predictor and Root Cause Analyzer—designed to help battery manufacturers significantly reduce R&D testing times and enhance overall battery manufacturing quality. This solution is also available as a Software as a Service (SaaS) model for faster, more flexible adoption that aligns seamlessly with evolving business demands.

How camLine’s AI-Driven Solution Accelerates Battery R&D Cycles While Maintaining Quality

AI-powered Battery Lifetime Predictor uses just 1.5% of data to speed testing

While AI models typically require 5 to 7% of total data, camLine’s Battery Lifetime Predictor accurately forecasts battery performance using only 1.5% of the battery cycle data—just 15 out of 1000 cycles. The model continuously integrates additional 5% of data for ongoing refinement, allowing manufacturers to dramatically shorten lengthy R&D testing periods and improve production throughput

AI-driven Root Cause Analyzer detects anomalies early with cross-process analysis

The Root Cause Analyzer collects detailed process parameters across multiple manufacturing steps, performing cross-process correlation analyses to pinpoint root causes of defects and inefficiencies. This proactive capability enables early anomaly detection, helping reduce downtime as well as improve yield and product quality consistency.

Benefits of camLine’s AI-Driven Solutions for Battery R&D and Production

- Accelerate Time to Market: Reduce R&D testing from weeks to hours, speeding product launches.

- Reliable Performance Prediction: Achieve accurate battery lifetime forecasts using minimal data.

- Improve Product Quality: Identify defect root causes to enhance product consistency and yield.

- Early Anomaly Detection: Detect issues early to enable faster corrective action and minimize downtime.

- Flexible Deployment: Offered as SaaS for scalable and rapid adoption that adapts to evolving business needs.

theion’s Success in Battery R&D Acceleration: Cutting Testing Times with 99.8% Prediction Accuracy

theion, a developer of sulfur-based battery cells, faced a 42-day R&D testing cycle that limited their speed to market. By implementing camLine’s Battery Lifetime Predictor, theion reduced testing time to just 15 hours, while achieving an outstanding 99.8% prediction accuracy. This breakthrough accelerated their development cycle by nearly 40 days.

Complementing this, camLine’s Root Cause Analyzer enabled theion to detect production anomalies early, allowing for faster issue resolution and reduced downtime. This leads to improved battery quality and higher production yield.

Subscribe to our newsletter

Get our latest updates and news directly into your inbox. No spam.