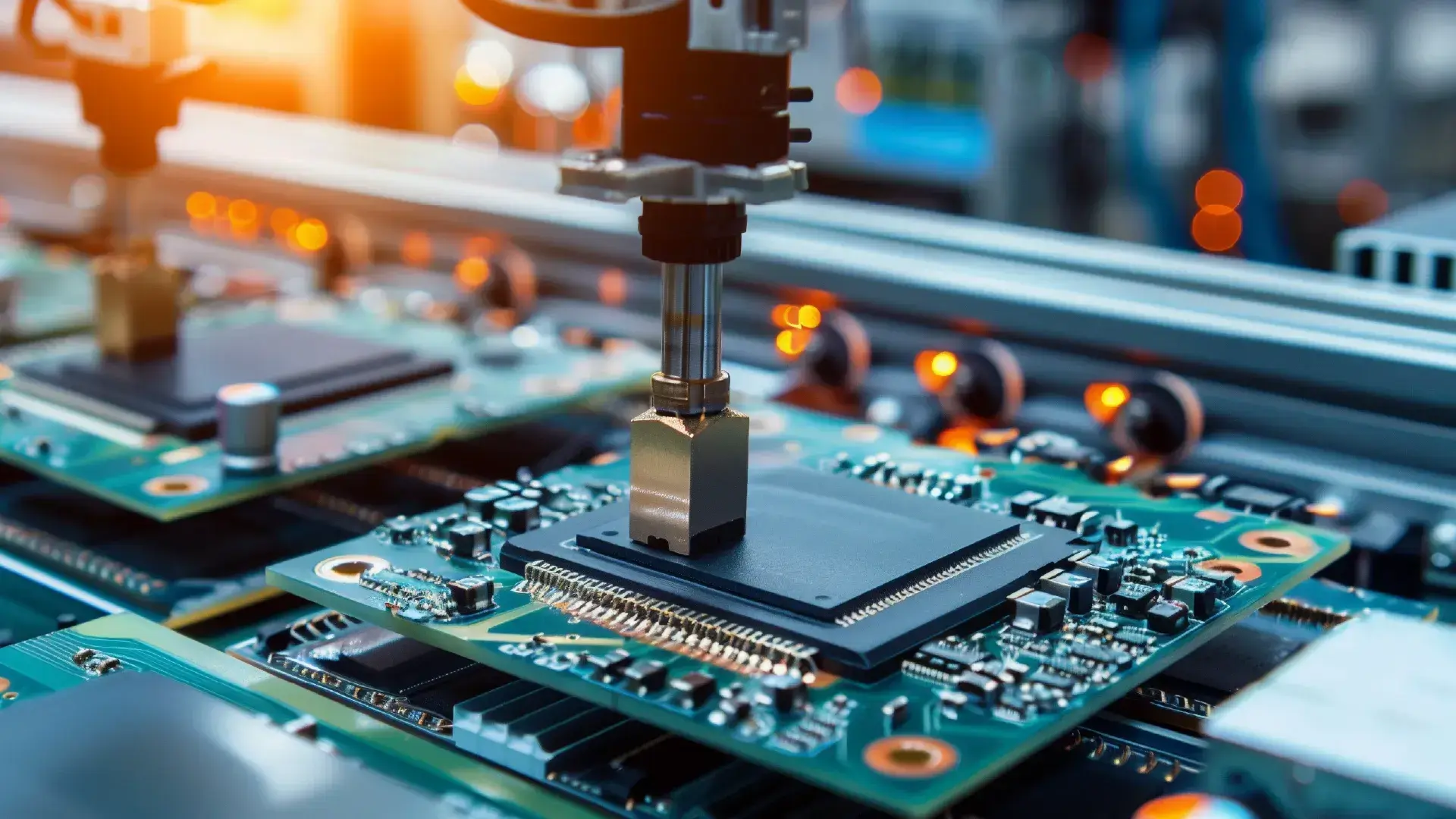

Semiconductor Frontend

Enable precise process control, full traceability, and cleanroom compliance in wafer fabs.

Explore how camLine MES, MOM, and AI-powered solutions supporting a wide range of manufacturers, from SMEs to global enterprises.

The pace of change in high-tech manufacturing continues to accelerate. Shorter innovation and development cycles, closer collaboration across supply chains, and the need for intelligent, integrated production environments are reshaping the challenges manufacturers face today.

To meet these demands, software solutions must evolve continuously and anticipate future requirements. Developed by camLine, our MES, MOM, and AI-powered solutions are designed to address these challenges and support the next generation of automation.

.png?width=149&height=100&name=Logos_ams-20250829-092441%20(1).png)

.png?width=303&height=100&name=Logos_azur%20space-20250829-092549%20(1).png)

Our MES and MOM solutions support manufacturers across diverse high-tech industries worldwide.

Enable precise process control, full traceability, and cleanroom compliance in wafer fabs.

Enhance yield, process integrity, and equipment coordination in assembly and packaging.

Optimize line setup, material control, and first pass yield in electronics assembly.

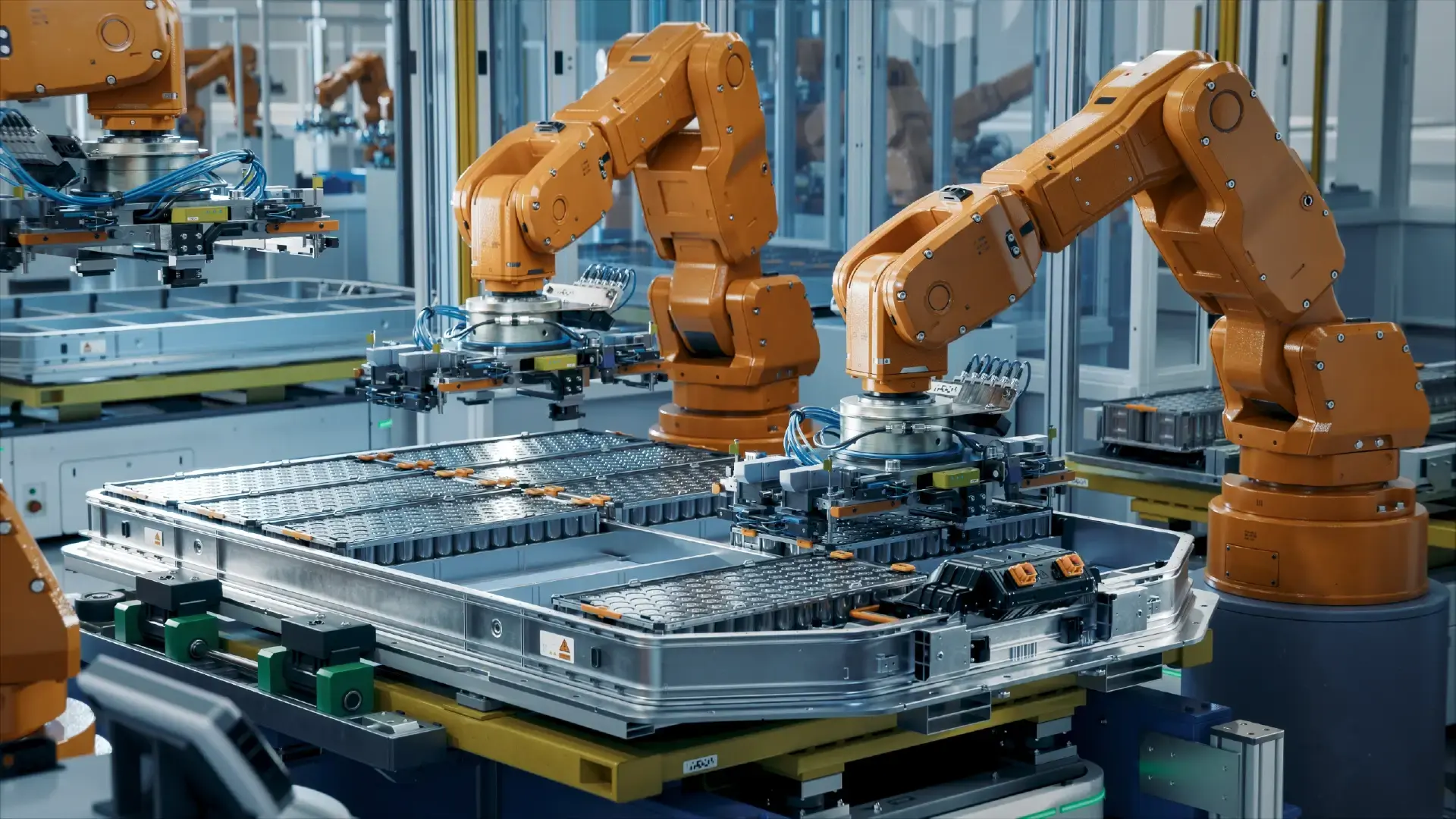

Ensure traceability, process stability, and consistent quality in battery and pack production.

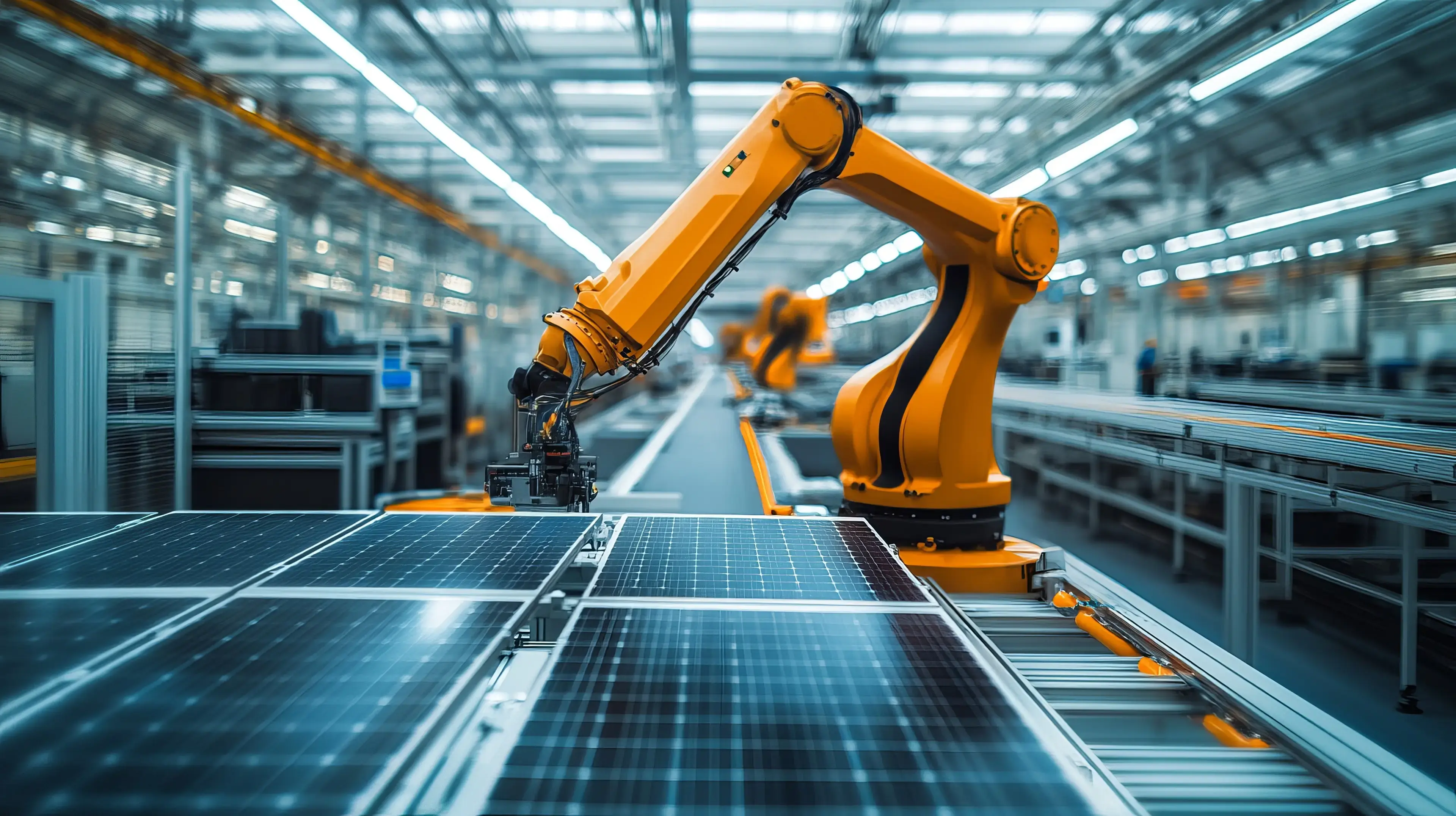

Automate production, improve quality, and enable cost-effective solar PV manufacturing.

Support compliance, end-to-end traceability, and product documentation in regulated manufacturing.

The mobility industry is undergoing rapid transformation as autonomous driving, electrification, shared mobility, and connectivity redefine vehicle design and production. Manufacturers face increasing complexity, strict quality expectations, and global supply chain challenges.

camLine supports real-time traceability and operational excellence with modular MES and MOM solutions that ensure zero-defect quality, JIT/JIS deliveries, continuous operations, and efficient production networks across Best-Cost Countries (BCCs).

With a proprietary infrastructure designed specifically for R&D organizations, camLine provides an integrated approach to knowledge management. Our MES and PDES solutions bridge gaps across the product life cycle, enabling seamless information exchange during technology development and supporting a smooth transition to large-scale production.

By linking experimental data, process insights, and design parameters within a unified environment, they enhance collaboration, efficiency, and traceability throughout R&D and production ramp-up.

With a proprietary infrastructure designed specifically for R&D organizations, camLine provides an integrated approach to knowledge management. Our MES and PDES solutions bridge gaps across the product life cycle, enabling seamless information exchange during technology development and supporting a smooth transition to large-scale production.

By linking experimental data, process insights, and design parameters within a unified environment, they enhance collaboration, efficiency, and traceability throughout R&D and production ramp-up.

Advances in materials technology often begin at the atomic level, where precise process control within tight tolerance ranges and coordination across the value chain are essential. Digitalization continues to transform materials research and production environments.

camLine MES module for Quality Assurance provides agile teams with a robust system landscape optimized for high data throughput. Production processes are further strengthened through online information and escalation management, supported by automated Out-of-Control (OOC) action plans that ensure consistent quality and fast response.

We believe successful software implementation requires more than great technology—it needs people who understand your business. Our co-development model with industry leaders ensures solutions address real-world challenges.

Explore how camLine MES/MOM solutions are applied in real manufacturing environments to address complex challenges across high-tech industries.

Discover how integrated recipe management with a digital twin for recipes streamlines workflows, enhances efficiency, and drives semiconductor manufacturing excellence.

Speed up root cause analysis and optimize semiconductor backend manufacturing with LineWorks SPACE Charts Trend Grouping Plug-in.

Gain real-time visibility into SMT production with a bird’s eye view capability, allowing you to plan, schedule, and optimize SMT production lines seamlessly.

Achieve full traceability in medical device manufacturing with InFrame Synapse MES. Ensure compliance and improve audit readiness with MES solution.

Cut battery R&D cycles from weeks to hours with camLine’s AI-powered Battery Lifetime Predictor and Root Cause Analyzer.

Explore our resource library to discover how camLine supports high-tech manufacturers in enhancing quality, efficiency, and reliability.

Discover how Axetris transformed semiconductor production by digitizing with MES—boosting efficiency, reducing errors, and enhancing traceability.

Learn how STMicroelectronics improves shopfloor analysis and anomaly detection with ML-driven advanced SPC solutions for better process control.

Discover how theion and camLine reduced battery R&D testing time from 42 days to 15 hours using AI-Driven predictive models data analysis.

Discover how B. Braun leverages camLine’s InFrame Synapse MES to enhance medical device manufacturing and achieve operational excellence.

Our team is ready to deliver tailored MES solutions that streamline your production, improve product quality, and maximize efficiency across your operations. Tap into camLine’s decades of expertise in digital transformation to overcome your manufacturing challenges.